The key technical specifications of ultrafine calcium carbonate—particle size, specific surface area, crystal form, and oil absorption—directly impact its application performance. While other indicators are important, they are relatively easy to achieve industrially. For specialized products, different applications place varying emphasis on various indicators and require different requirements.

Particle Size and Specific Surface Area

The fundamental requirement for ultrafine calcium carbonate is that the average particle size of its primary particles must fall within the range of 0.02∼0.1μm. This is the very basis of its “ultrafine” characteristic. However, achieving this only fulfills half the task. If surface treatment and dispersion technologies are inadequate, the primary particles will aggregate into large secondary particles, which can be several hundred nanometers in size.

Therefore, a scientific and comprehensive assessment of UCC’s fineness, crystal morphology, and dispersion status requires the combined use of Transmission Electron Microscopy (TEM) observation and specific surface area measurement.

To effectively prevent the agglomeration of secondary particles, ultrafine calcium carbonate typically undergoes surface modification treatment. This process is crucial not only for improving the activity of UCC but also for inhibiting the formation of secondary particle aggregates.

The production of ultrafine calcium carbonate relies heavily on precise grinding. Advanced equipment such as jet mills or high-energy ball mills are used to achieve the desired particle size. Jet mills utilize high-speed airflow to drive particle collisions, ensuring uniform particle size distribution and high purity. High-energy ball mills provide intense mechanical grinding to refine particles. Both methods require precise control to avoid over-grinding that could alter the crystal structure or introduce impurities.

Crystal Morphology

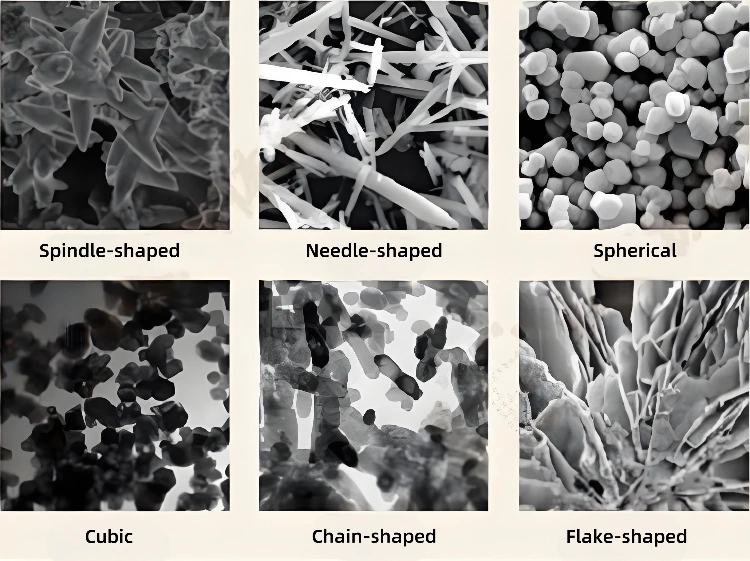

Crystal morphology is another vital technical index for ultrafine calcium carbonate.

It is well-known that ordinary light calcium carbonate is spindle-shaped. When used in PVC plastics, it can induce significant stress, leading to a whitening phenomenon in the plastic film. Therefore, UCC products should have different crystal morphologies tailored to their specific applications.

- Plastics Application: Requires simple crystal structure, small bulk volume, and low oil absorption value. Cubic or spherical shapes are preferred. For instance, UCC with a particle size of approximately 0.072μm can enhance PVC plastics, resulting in products with a fine, smooth surface, good gloss, and excellent electrical insulation. When used in soft cable materials, performance standards can be met even when the filler amount is more than doubled. In plastic films, it reduces whitening and improves low-temperature elongation. In rigid plastics like doors, windows, and profiles, it increases impact strength, with notched impact strength reaching up to 49.1kJ/m2.

- Rubber Application: Chain-like morphology provides the best reinforcing performance. Chain-like UCC consists of several to dozens of crystallites connected in one direction, forming a spatial network structure with excellent dispersibility in rubber. During mixing, the UCC chains break, creating active fracture surfaces that bond more strongly with the rubber chains, significantly boosting the reinforcing effect. The order of reinforcing performance in rubber, from strongest to weakest, is: Chain-like > Acicular (Needle-like) > Spherical > Cubic.

- Ink Application: Cubic morphology is optimal for resin-based inks, which require high gloss, good transparency, and excellent flowability. The cubic shape is most beneficial for ink gloss.

- Paper Coating Precipitated Calcium Carbonate (PCC): Although most of its particle sizes (0.1∼1μm) fall within the fine calcium carbonate range, it also has specific crystal morphology requirements to meet demands for opacity (covering power), high solids content viscosity, whiteness, and ink absorption properties. Platy (Plate-like) and Cubic morphologies are considered ideal.

Oil Absorption Value

The oil absorption value is crucial for ultrafine calcium carbonate’s application performance, especially in plastics, coatings, and inks. A high oil absorption value will consume a large amount of plasticizer in plastics or drastically increase the viscosity of coatings and inks. Consequently, the oil absorption value must not be excessively high.

Many factors influence a powder’s oil absorption value. Apart from the intrinsic physical properties of the substance, powder particle size is a significant contributing factor.

Main Content

The main content (Calcium Oxide content) of ultrafine calcium carbonate should not be too strictly limited within a certain range. This is because, in most applications, UCC serves as a functional filler, affecting the filled material primarily through physical properties, which are generally satisfied by the main content within a reasonable range.

During preparation, various control agents, dispersants, and surface treatment agents are added. These additives help achieve specific crystal morphologies and good dispersion. They also improve activation performance to meet the needs of plastics, rubber, and inks. These intentionally added “impurities” usually have no negative impact on, and can even benefit, UCC’s application performance. However, their inclusion inevitably affects the measured main content (Calcium Oxide).

Nonetheless, harmful elements such as iron and manganese must be strictly controlled. They may come from raw materials or during preparation. These impurities negatively affect the color of the final product. They also accelerate the degradation and aging of the resin. Other impurities like silicon, aluminum, and magnesium reduce the whiteness of UCC. They can also interfere with processing operations. Therefore, strict control is required when selecting limestone raw materials.

Epic Powder

The superior performance of ultrafine calcium carbonate stems from the precise control of its key indices—especially particle size, crystal morphology, and surface activity. In industrial production, high-quality grinding and preparation technology is essential for achieving these specifications. Whether through traditional wet/dry milling or more advanced mechanical activation, the performance of the grinding equipment directly determines the ultimate fineness and dispersibility of the product. Advanced grinding technologies and equipment, exemplified by Epic Powder, are focused on delivering more efficient and energy-saving solutions. These innovations help manufacturers precisely control the particle size distribution and crystal morphology of UCC, ensuring its optimal functionality in various specialized applications, and driving further innovation and development in the fields of plastics, rubber, and inks.