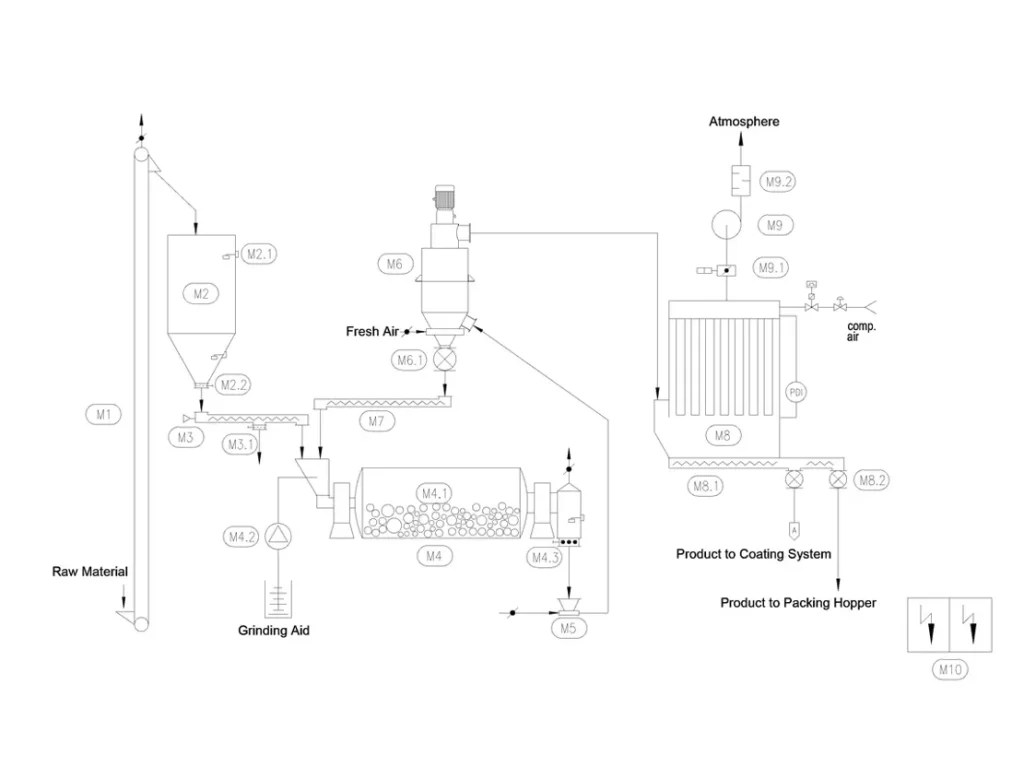

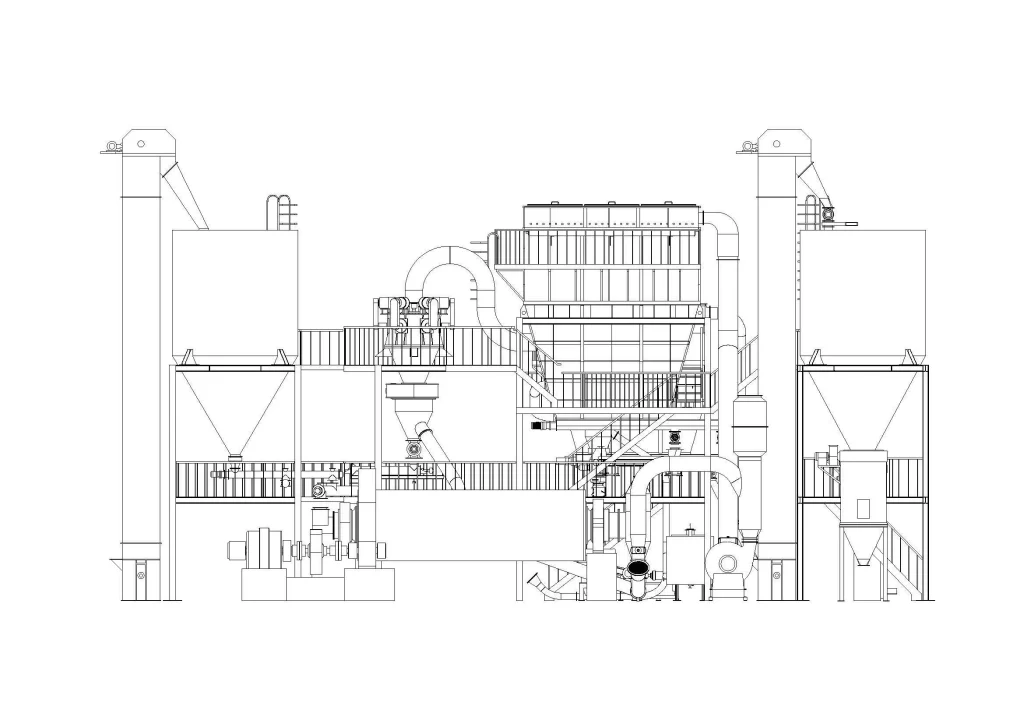

Calcium carbonate Ball Mill and Classifier Production Line

International standard processing line, used with classifier, can produce products with multiple particle size at the same time.

Features:

The product particle size control is flexible, special design is adopted to reduce noise and emission; Automatic control, easy to operate, According to the scale of investment, it provides personalized customized scheme and provides value-added services.

Application:

Calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine cement, slag, steel slag.

Calcium carbonate (CaCO3), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on Earth.

Calcium carbonate is not only the main component of marble, limestone and dolomite, it is also found in bones and teeth as well as the exoskeleton of crustaceans, coral, muscles, snails and protozoa. A further modification of CaCO3 is the mineral vaterite, which precipitates out of supersaturated solutions in the form of microscopic crystals.

There are many varied uses for calcium carbonate:

- As raw material for the construction material industry (manufacture of cement and quick lime or limestone for building and road construction)

- As aggregate in the steel industry

- As abrasive and polishing agent in toothpaste

- As mineral fertilizer

- And as mineral filler or pigment in diverse industrial applications (paper, paint, plaster, plastic, carpet)

In addition to kaolin and talc, calcium carbonate is used in the paper industry as a filler and coating pigment in the production of paper. Since calcium carbonate is rhombohedral even when very finely ground, it is primarily used in papers with the highest degree of whiteness and good printability. Examples of these are coated printing papers or highly filled copy and office papers.

Major equipment of Calcium carbonate ball mill grinding production line

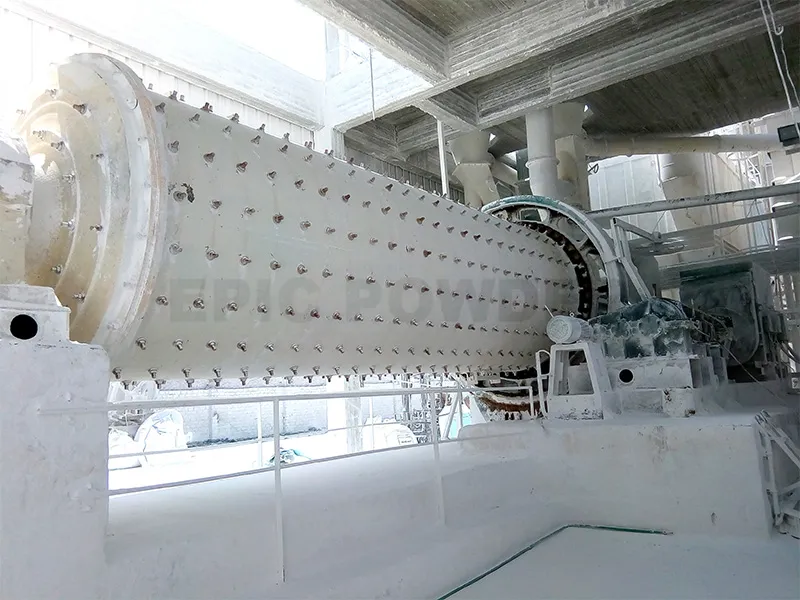

Ball mill

- The ratio of length to diameter of ball mill is optimized to provide more ideal output and fine powder rate, avoid excessive grinding and improve grinding efficiency;

- The size of grinding cavity and opening are optimized. Feeding and discharging are smooth, no need cooling pipe;

- The lining plate and grinding medium are manufactured according to German standards, which extend the service life of the grinding medium and improve the wear resistance. According to the requirements of product fineness, the size and material of grinding medium are designed to improve the grinding efficiency;

- The grinding energy consumption is reduced to the greatest extent, and the energy and operation cost are saved.

Classifier

- Originated from German technology, it is divided into vertical turbine classification and horizontal turbine classification;

- Accurate frequency conversion control ensures perfect classification accuracy;

- The structure of the classifier is optimized, the path of material and air flow is more reasonable, the air volume of classification is adjustable, the classification efficiency and flexibility are improved;

- The new NG rotor design improves the classification accuracy, reduces the resistance and reduces the energy consumption.

Powder Surface Modification

Powder surface modification is an inevitable product of modern high-tech and new material development. Powder modification not only can improve the performance of the powder, but also can improve its practical value and broaden its application field.

We have 4 types of powder coating modification equipment:

Turbo Mill for Powder Coating

Technical parameters of ball mill grinding and classifying production line

| Parameter / Model | 1530 | 1557 | 1850 | 1860 | 1870 | 2250 | 2260 | 2270 | 2450 | 2460 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder diameter (m) | 1.5 | 1.5 | 1.83 | 1.83 | 1.83 | 2.2 | 2.2 | 2.2 | 2.4 | 2.4 |

| Cylinder length (m) | 3 | 5.7 | 5 | 6 | 7 | 5 | 6 | 7 | 5 | 6 |

| Motor power (kw) | 75 | 132 | 160 | 220 | 250 | 250 | 320 | 380 | 320 | 400 |

| Feeding size (mm) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Fineness (um) | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 | 5-75 |

Projects

Projects in these field

Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made

Calcium carbonate (CaCO₃) is a widely used inorganic non-metallic material,

Calcium Carbonate Is Reshaping the Plastic Composites Industry

In the history of the plastics industry, calcium carbonate has

Calcium Carbonate — The “Grain of Industry”

In modern industrial systems, calcium carbonate (CaCO₃) is known as

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS