Horizontal Air Classifier

- Features:

High speed, accurate vertex cutting; clean production process; program control system, easy to adjust and operate. - Application:

Widely used in mineral industry (especially suitable for classification of non mineral products such as calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, refractory, medicine, pesticide, food, health care products, new materials, etc..

Horizontal Air Classifier working principle

German classifier experts created the HTS series airflow classifier. It efficiently classifies dry materials sized from 3 to 45 microns. This classifier is specifically for ultra-fine powders. Its internal grading rotor rotates at high speed. The rotor is installed horizontally. The classifier, cyclone collector, dust collector and induced draft fan form a complete classification system. The induced draft fan pulls material into the classification cavity. The classifying rotor blocks coarse particles with centrifugal force. The fan’s gravity removes fine powder. The fine powder passes through the gap between the blades of the classifying wheel. It then enters the cyclone collector or the dust collector to separate coarse and fine materials. Coarse particles entrain some fine particles. They lose speed after hitting the wall and descend to the secondary tuyere. This happens along the cylinder wall. Fine particles move to the classification area after being separated. Particles descend to the discharge port for discharge. They may also return to the crushing equipment for further crushing and grinding.

Features of Horizontal Air Classifier

Single Classifying Wheel Working Principle

- A horizontal mounted staged rotor, linear speed can reach 100m/s;

- The rotor speed can be adjusted by frequency conversion, and the force distribution can be adjusted flexibly;

- Suitable for precise classifying of dry micron material;

- Available D50:1.5-25μm.

Multiple Classifying Wheel Working Principle

- The rotor diameter is 315mm-630mm, and 2-6 rotors, which is used for ultra-fine powder classification;

- The classifying wheel increases the classifying space on the top of silo;

- Inverter control, adjustable speed;

- Higher output than single rotor.

Single Classifying Wheel Technical Parameters

| Parameter / Model | 70 | 100 | 140 | 200 | 260 | 315 | 400 | 500 | 630 | 750 | 1000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Particle size(D97:μm) | 5-100 | 3-100 | 3-120 | 3-120 | 3-150 | 3-150 | 4-150 | 5-150 | 6-150 | 6-150 | 15-150 |

| Classification efficiency(η) | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% |

| Classifier motor(kW) | 2.2 | 3 | 4 | 7.5 | 11 | 15/18.5 | 18.5/22 | 22/30 | 30/45 | 37/55 | 45/75 |

| Air volume(m³/h) | 150 | 300 | 600 | 1200 | 2000 | 3500 | 5600 | 8800 | 14000 | 20000 | 35000 |

Multiple Classifying Wheel Technical Parameters

| Parameter / Model | 200/4 | 315/3 | 315/4 | 315/6 | 400/6 | 500/3 | 500/4 | 500/6 | 630/6 |

|---|---|---|---|---|---|---|---|---|---|

| Particle size(D97:μm) | 5-100 | 3-100 | 3-120 | 3-120 | 4-150 | 5-150 | 6-150 | 6-150 | 6-150 |

| Classification efficiency(η) | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% | 60~80% |

| Classifier motor(kW) | 2.2 | 3 | 4 | 7.5 | 11 | 18.5/22 | 22/30 | 30/45 | 37/55 |

| Air volume(m³/h) | 150 | 300 | 600 | 1200 | 2000 | 5600 | 8800 | 14000 | 20000 |

Projects

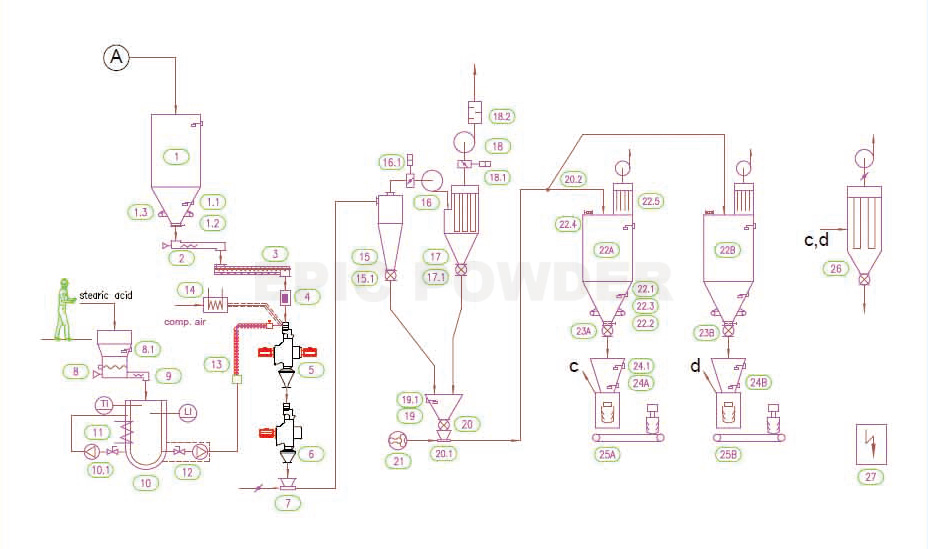

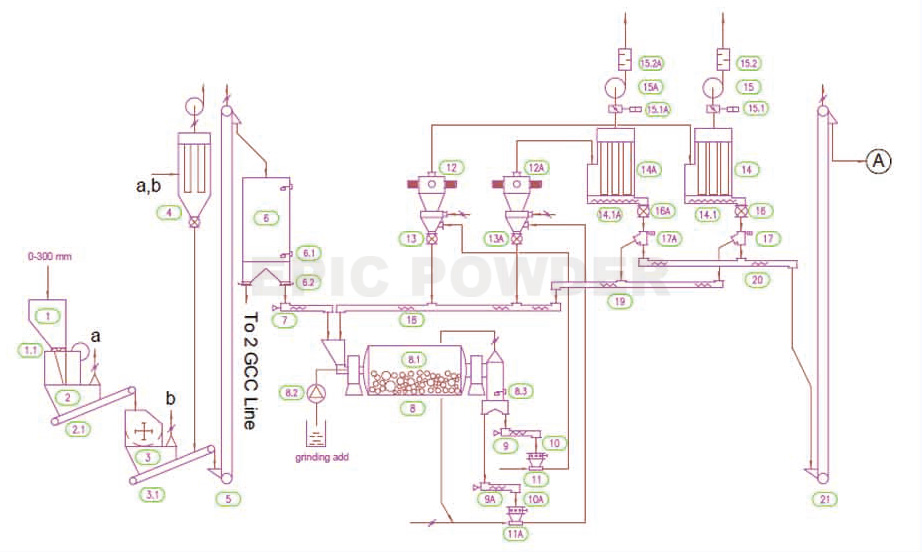

Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made

Calcium carbonate (CaCO₃) is a widely used inorganic non-metallic material,

Calcium Carbonate Is Reshaping the Plastic Composites Industry

In the history of the plastics industry, calcium carbonate has

Calcium Carbonate — The “Grain of Industry”

In modern industrial systems, calcium carbonate (CaCO₃) is known as

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS