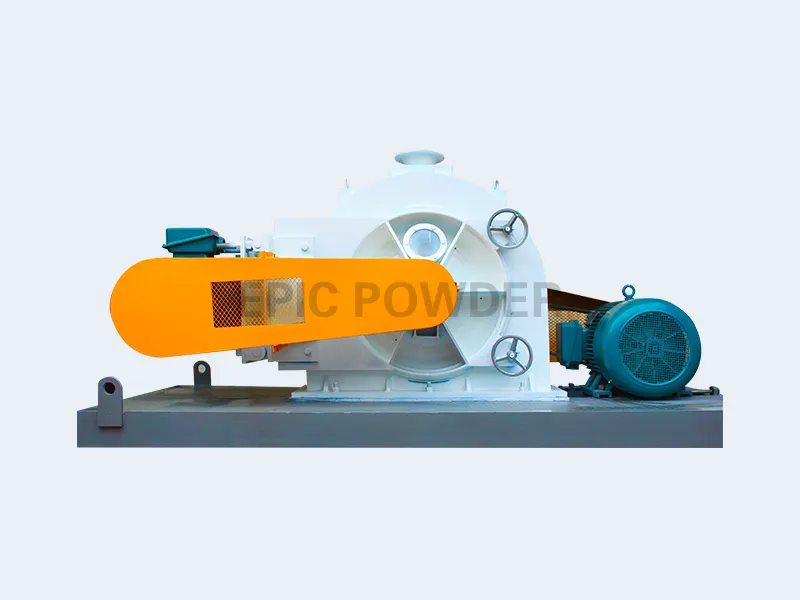

Pin Mill for Powder Coating

- Pin mill with 2 driven pin discs for achieving high powder fineness values in the range of approx. 10 to 500 µm

- The wide chamber housing makes it possible to process even sticky materials

- Generously dimensioned mill door

- Easy to clean for product changes

- Optional: Versions for Pharma applications

- Optional: Versions for coating applications

What is Pin Mill

The EPIC Powder PM-C pin mill is a high-performance fine impact pin mill for continuous use. It has the ability to process a wide range of raw, often challenging, materials up to a Mohs hardness of 3 (or contaminations less than 0.1%) into very fine, contamination-free, powders in the range of 10µm to 500µm.

Material feeds into the centre of the mill, where it is processed and normally discharges from the bottom outlet. However, the mill can be configured with a tangential direction discharge, upon request.

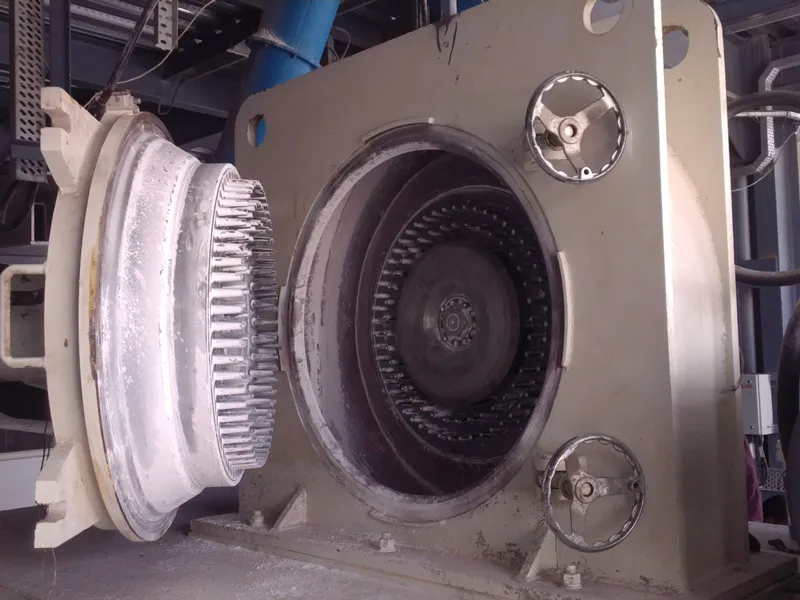

The PM-C pin mill’s performance relies on two adjustable, counter-rotating pin discs. The discs are located on the door side and machine side. The discs spin at high speed, faster than a single pin disc. This pin disc is interchangeable with the MJL-P pin mill.

The pins are available in standard special steel and other materials meeting high hygiene, wear, and contamination standards.

The unique PM-C pin mill’s pin discs can operate at speeds up to 240m/sec at the outermost rows of pins. This speed is ideal for processing brittle materials. The speed can also be adjusted lower to manage the fineness of the material.

The strong centrifugal force in the mill’s oversized chamber processes moist, greasy, sticky, and hydroscopic material easily. Deposits on pins or in the grinding chamber can impact the mill’s performance. In addition, liquid nitrogen can be introduced to permit cryogenic milling of heat-sensitive materials such as spices.

The mill’s motors optimize transmission ratios for the process and product. This improves energy efficiency because the motor and disc work better together.

You can set the rotational direction and disc speed of the pin discs. Adjust the air flow and feed rates to process various materials. This includes heat-sensitive ones. The mill can homogeneously mix and grind two or more materials. It’s an added benefit of the PM-C pin mill.

A high-quality system monitors the mill’s two bearing units. It assesses temperature and vibration levels continuously. This allows for prompt preventative maintenance when necessary. Rinsing air stops product from entering bearing units. It prevents material from depositing behind pin discs, maintaining the mill’s performance. The bearing units are permanently lubricated and easy to replace when needed.

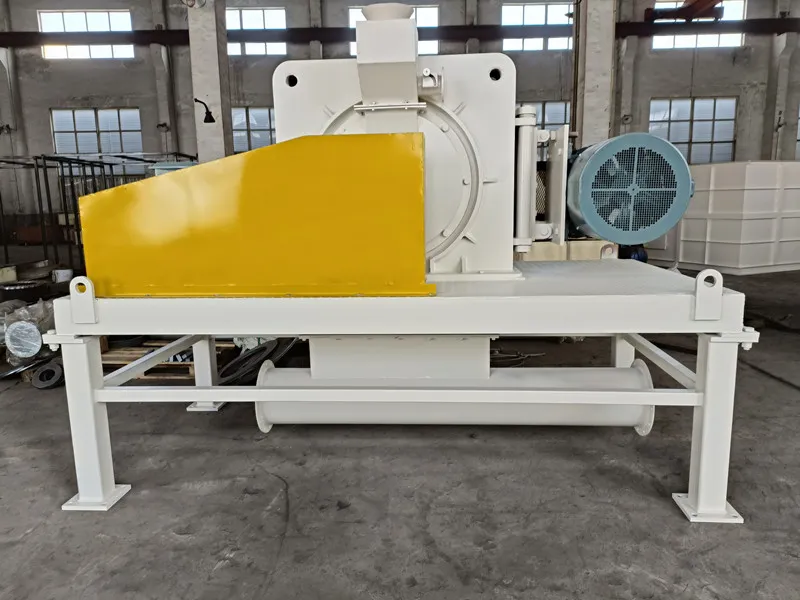

The mill’s door is generously sized for easy access. It is specially hinged to aid cleaning and maintenance.

Pin Mill Coating Machine Working Principle

The pin mill is a fine impact mill with two driven pin discs. In counter-rotating mode, much higher relative speeds are possible than with the MJL-P fine impact mill with only one driven pin disc. The highest relative speed develops at the outermost pin rows and can be up to 240 m/s.

The strong centrifugal force in the grinder disperses calcium carbonate powder and stearic acid liquid. This ensures even application of stearic acid modifier on each powder particle. The result is a high coating effect and rate.

Features of Pin Mill

- Pintype crushing disc, no screen structure, fast speed, large capacity and low heat generation.

- Single power or double power can be selected, the line speed can reach up to 240m/s, strong impact force and shear force, and the product particle size is fine.

- It is suitable for dispersing and deagglomerating

- It is suitable for continuous high-speed mixing for ultrafine powder and liquid, and particle surface coating modification.

- It can be equipped with an air classifier to control the product fineness.

- Compact in structure, the mill is extremely easy to disassemble and clean.

Pin Mill Technical Parameters

| Type | Model | 250 | 400 | 500 | 630 | 800 |

|---|---|---|---|---|---|---|

| Grinding Motor Power(kW) | Fineness(mesh) | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 | 20 - 200 |

| speed(m/s) | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | 75 - 85 | |

| power(kw) | 7.5 | 18.5 | 22 | 37 | 55 | |

| Blade speed(m/s) | Fineness(mesh) | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 | 60 - 300 |

| speed(m/s) | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | 100 - 120 | |

| power(kw) | 15 | 30 | 37 | 55 | 75 | |

| Ultra fine powder | Fineness(mesh) | 100-2500 | 100-2500 | - | 100-2500 | 100-2500 |

| speed(m/s) | 200-240 | 200-240 | - | 200-240 | 200-240 | |

| power(kw) | 15 x 2 | 30 x 2 | - | 30 x 2 | 30 x 2 |

Pin Mill Coating Machine Site Pictures

Brochure Pin Mill PDF

Projects

Projects in these field

Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made

Calcium carbonate (CaCO₃) is a widely used inorganic non-metallic material,

Calcium Carbonate Is Reshaping the Plastic Composites Industry

In the history of the plastics industry, calcium carbonate has

Calcium Carbonate — The “Grain of Industry”

In modern industrial systems, calcium carbonate (CaCO₃) is known as

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS