Three-roller Coating Machine

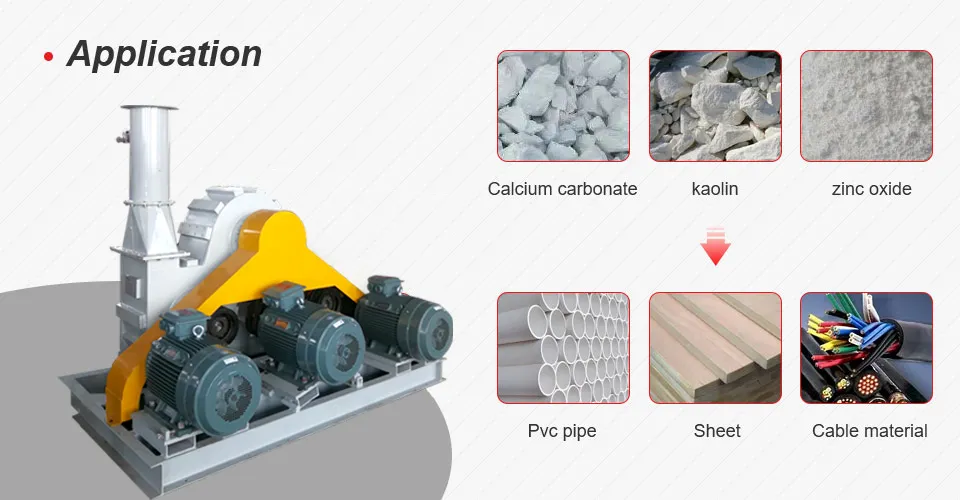

This equipment is a continuous surface coating machine. Especially suitable for surface modification of powders such as calcium carbonate, kaolin, graphite, talc, silica micropowder, magnesium hydroxide, barium sulfate, etc.

Coating rate: More than 95%

Capacity: 500-7500kg/h

What is Three-roller Coating Machine

Modern high-tech and new materials drive powder surface modification. Powder modification not only can improve the performance of the powder, but also can improve its practical value and broaden its application field.

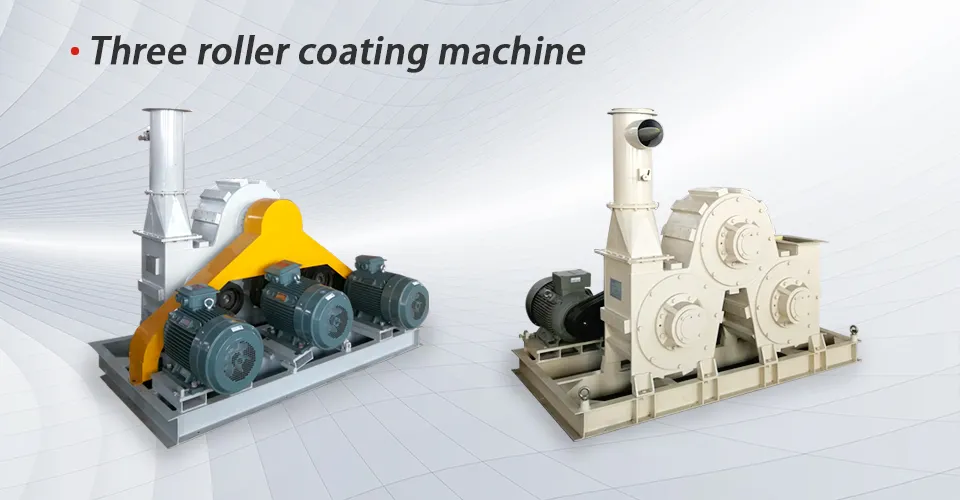

The three-roller coating machine is a kind of self friction and continuous powder surface modification machine. It is especially suitable for the surface modification of ultra-fine powder. It has no dust pollution in production and is easy to operate. Customers welcomed it when introduced. The machine is named three-roller coating because it uses three rotating rotors to modify powder surface flow.

Three-roller Mill working principle

The double screw feeding system feeds material from the storage silo into the modification machine. The metering pump measures the modifier and introduces it simultaneously with the material. Using a solid modifier involves heating it until melted in a controlled system.

The main machine is composed of three modified cylinders in a triangular shape. The modifier and powder enter the first cylinder. It happens automatically and continuously. When they flow through each modified cylinder, they are impacted by airflow in different directions. The high-speed rotor creates a vortex in the modified cylinder. This fully breaks up the material and the modified agent.

The rotor’s high-speed rotation generates heat to warm up the powder in the barrel. This allows the modifier to mix with the powder easily. The modifier interacts evenly with the powder particles, coating them for surface modification.

Under negative pressure, the finished product is cooled and collected by a cyclone dust collection system. A small amount of powder is then completely collected by a pulse dust collector.

Features of our three roller coating machine

The main machine has three modification chambers. They are distributed triangularly with a compact structure. The heat generated by the high-speed rotation of the stator and rotor modifies without extra heating. Low investment and operating costs.

This coating machine can run continuously with high output. It is suitable for various scales of industrial production.

Accurate measurement of the ratio of powder and modifying agent. High usage rate of modifier and low consumption. Good modification effect of powder and high coating rate.

Adopt metering spiral feeding. Use frequency conversion to adjust the spiral speed for stable feeding.

The dosing system is electrically heated. It has a temperature sensor and adjustable heating temperature. It is suitable for different solid modified chemicals.

Our three-roller coating machine has a double cyclone separator for high separation efficiency. It is also equipped with pulse type bag dust collector, high dust removal efficiency, large filtering area, not easy to block.

It uses a unique mixing method for efficient modification without altering the powder’s shape.

The three-rpller coating machine has both modifying and dispersing functions, and is suitable for materials of various finenesses. It uniquely modifies materials with low density and high visibility, like barium sulfate, white carbon black, mica powder, and talcum powder.

Materials operate under negative pressure, with good sealing to prevent dust leakage. It minimizes pollution, creating a positive work environment. It also has low labor intensity.

Components of three-roller coating machine

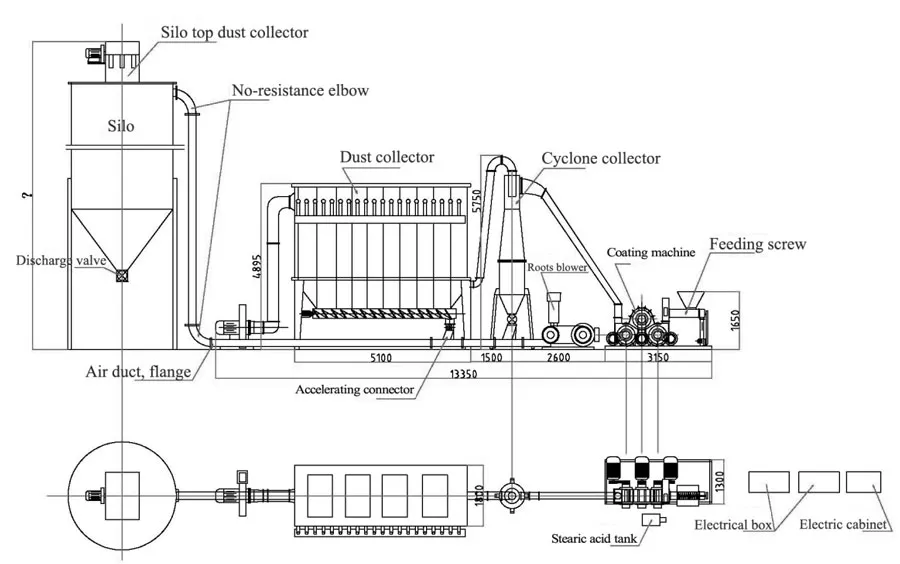

The three-roller coating production line is made up of feed screws, main coating machine, roots blower, cyclone dust collector, bag dust collector, storage silo, stearic acid tank, electric control cabinet, and other parts.

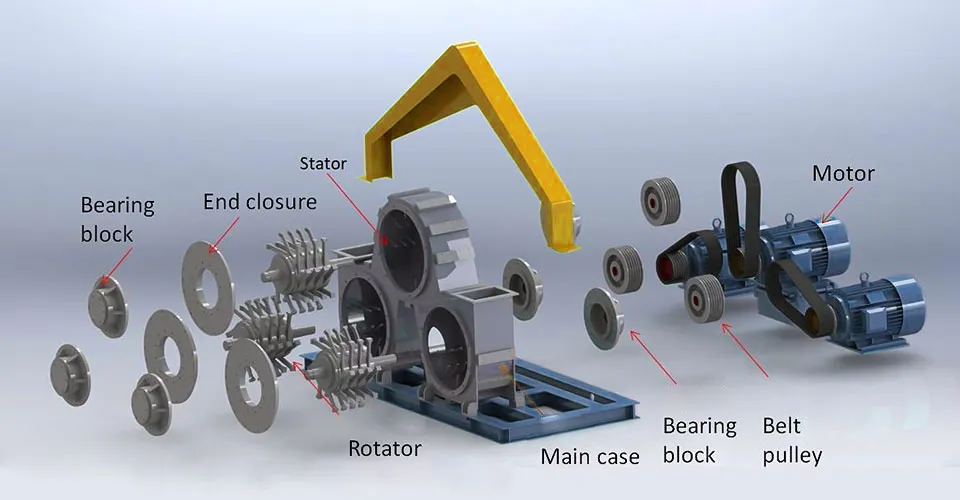

Among these, the main machine includes the bearing block, end closure, stator, rotator, main case, belt pulley, motor, and other parts.

Wide Applications of Three Roller Coating Machine

The three-roller coating machine is suitable for modifying 325 to 1250 mesh powders, such as calcium carbonate, kaolin, zinc oxide, magnesium hydroxide, strong alumina, sericite, barium sulfate, white carbon black, titanium dioxide, talc, graphite, silica micropowder, barium sulfate, etc.

The modified calcium carbonate powder enhances dispersion and bonding in polymer matrices, such as polyolefin. This creates a unique cladding structure on the surface. This process creates interfacial interaction with the polymer matrix, enhancing the impact strength of the product. It is an additional filler with excellent performance.

Three-roller Mill Technical Parameters

| Model | Motor(kw) | Speed(RPM) | Fineness(Mesh) | Capacity(kg/h) | Temperature(℃) |

|---|---|---|---|---|---|

| CRM-3 | 18.5x3 | 4500 | 325-3000 | 500-1500 | 80-120 |

| CRM-6 | 37x3 | 2700 | 325-3000 | 1200-3700 | 80-120 |

| CRM-9 | 75x3 | 2000 | 325-3000 | 2000-7500 | 80-120 |

Why choose EPIC Powder’s three-roller coating machine?

EPIC Powder Machinery, a powder machine processing solution supplier, has over 10 years of experience. We lead in modifying non-metallic powders in China. We offer the best solutions for our customers. Up to now, we have provided high quality products and technical support to customers in many countries such as Egypt, Vietnam, India, etc.

Furthermore, in addition to the modification equipment, we can also provide grinding equipment. You can add grinding equipment before the modification equipment. Our technical staff will create a suitable solution for you. If you have any issues with the equipment, our technicians are available on-site to assist you promptly.

If you need a reliable supplier of modification machinery, don’t hesitate to contact us. You won’t have any worries using our equipment.

Projects

Projects in these field

Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made

Calcium carbonate (CaCO₃) is a widely used inorganic non-metallic material,

Calcium Carbonate Is Reshaping the Plastic Composites Industry

In the history of the plastics industry, calcium carbonate has

Calcium Carbonate — The “Grain of Industry”

In modern industrial systems, calcium carbonate (CaCO₃) is known as

30M

RESPOND WITHIN 30 MINUTES

24H

PROVIDE TECHNICAL SOLUTIONS IN 24 HOURS

2H

REPLY TO CUSTOMER QUESTIONS IN 2 HOURS

72H

PROVIDE SOLUTIONS WITHIN 72 HOURS