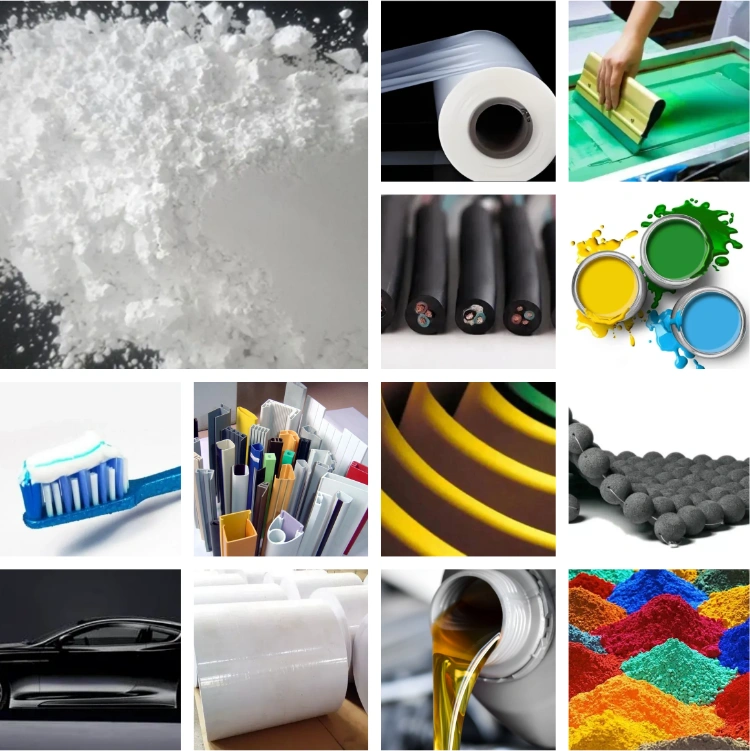

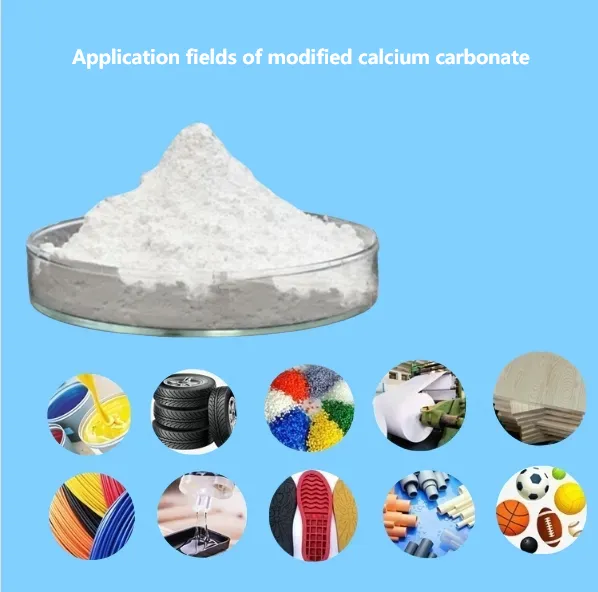

Surface modification is crucial for enhancing calcium carbonate‘s performance, applicability, and market expansion. In the future, functionalization and specialization will be the main trends in calcium carbonate development. The demand for surface modified calcium carbonate will continue to grow. It’s essential to base surface modification on its mechanism. Consider the substrate, formulation, and technical requirements of downstream organic polymer products. Select a suitable surface modifier after comprehensive evaluation. Choose the appropriate modification process and equipment. Only then can qualified active calcium carbonate products be produced. Modified Calcium Carbonate is increasingly used in various industries to enhance material performance and meet specific technical requirements.

Polyvinyl Chloride (PVC)

Compared to regular calcium carbonate, Modified Calcium Carbonate has particles evenly distributed in their original particle form, without agglomeration. It has excellent compatibility and dispersibility with PVC resin, is easy to plasticize, does not stick to rollers, and has excellent processing performance. This improves processing efficiency and significantly enhances the product’s tensile strength and elongation at break, resulting in excellent physical and mechanical properties.

Polypropylene (PP)

By modifying lightweight calcium carbonate with the coupling agent tetrahydrofuran homopolymer ether (PTHF), its oil absorption value can be reduced to 22%, and the contact angle to 68.6°. The modified calcium carbonate disperses well in polypropylene and helps mitigate the decline in tensile strength. As a result, the composite material’s elongation at break reaches 28.47%, and its impact strength improves to 6.7 kJ/m².

High-Density Polyethylene (HDPE)

Heavy calcium carbonate is mechanically and chemically modified with aluminum stearate coupling agents. The coupling agent forms bonds on the calcium carbonate particles’ surface, significantly improving their dispersion. As the amount of modified calcium carbonate increases in HDPE, the composite material’s abrasion and friction work decrease, improving its friction resistance. When the content is 8 phr, the composite material shows optimal mechanical properties, with tensile strength and impact strength increasing by 4.46% and 24.57%, respectively.

Low-Density Polyethylene (LDPE)

Stearic acid (1.5%) and DL-411 aluminum stearate (0.5%) are used to modify calcium carbonate. The modified calcium carbonate has an activation index of 99.71%. Its oil absorption value is 46.19 mL/100g. The final sedimentation volume is 2.3 mL/g. Its viscosity is 4.4 Pa·s when mixed with 10g of modified calcium carbonate and 100 mL liquid paraffin. When filled into LDPE, the composite material shows excellent mechanical properties. This occurs when the modified calcium carbonate content reaches 10%.

ABS Plastics

After surface modification, nano-calcium carbonate in ABS plastics shows improved dispersion. It changes from hydrophilic to oleophilic. When incorporated into ABS resin, it enhances mechanical properties. These properties include impact strength, tensile strength, surface hardness, and bending strength. It also improves thermal properties, such as heat distortion temperature.

Polyester (PBAT)

Using a double-layer coupling agent coating method, calcium carbonate is surface-modified for use in PBAT. The modified calcium carbonate loading can reach up to 50%, and the composite material shows excellent overall mechanical performance. In the composite, the modified calcium carbonate particles are completely infiltrated and coated by the PBAT resin matrix without any dissolution, enhancing the mutual flowability between the two.

Radiation Crosslinked Ethylene Propylene Diene Monomer (EPDM)

A titanium ester coupling agent (105), with unsaturated functional groups, is used for in-situ modification of calcium carbonate. This improves the dispersion of modified calcium carbonate. In the radiation-crosslinked EPDM, the surface of modified calcium carbonate reacts with the oil acid groups in EPDM, incorporating the calcium carbonate into the crosslinking network of EPDM. This increases the composite’s tensile strength, 100% elongation stress, and Shore A hardness, imparting reinforcing properties to calcium carbonate in radiation-crosslinked EPDM.

Polylactic Acid (PLA)

Surface modification of calcium carbonate with coupling agents increases the specific surface area of the calcium carbonate. This results in a larger contact area with the matrix, generating more silver streaks and plastic deformation zones under stress. This absorbs significant amounts of energy, thereby improving toughness and strength.

PVC-Coated Fabrics

Modified heavy calcium carbonate improves PVC resin blend compatibility, reducing viscosity and enhancing adhesion to polyester fabrics. It reduces adhesive use and improves tactile feel. Even with a 40% increase in content, it doesn’t affect processing or mechanical properties.

PVC Fire Pipes

Modified calcium carbonate particles are evenly distributed and some exist as nanomaterials. When used in PVC fire pipes, it improves processing performance and enhances physical and mechanical properties, providing reinforcement and toughness.

PVC Cable Materials and Flame Retardant Masterbatch

Aluminate, titanate coupling agents, and stearic acid modify heavy calcium carbonate. This modified filler is used in PVC cable materials and flame retardant masterbatch, offering excellent performance. The use of composite modifiers will be a trend in surface modification of heavy calcium carbonate.

Polyether Ether Ketone (PEEK)

Sulfonated hyperbranched poly(aryletherketone) modifies calcium carbonate whiskers. This improves dispersion, enhances interaction between phases, and reduces melt viscosity. The composite material’s Young’s modulus, flexural modulus, and toughness are increased.

Plastic Films

Calcium carbonate is widely used in plastic films. After surface treatment, calcium carbonate is uniformly dispersed, bonding to resin via adsorption, physical entanglement, and van der Waals forces, resulting in improved film performance.

Food Plastic Packaging

Nano-calcium carbonate, as a filler in plastic packaging, has special effects in improving product performance. Studies show nano-food packaging materials possess barrier, antibacterial, and preservation properties. They are used in beer, beverages, fruits, vegetables, and dairy packaging. To achieve good dispersion and small particle size, nanomaterial energy must be reduced, often through mechanical dispersion or by adding dispersants or drying.

Breathable Films

Breathable films are made by blending around 50% specialty calcium carbonate with PE or PP carriers. After extrusion and stretching, they are widely used in medical films, surgical gowns, gloves, sanitary napkins, diapers, disposable bed sheets, fresh-keeping films, composite films, and cooked food packaging. Surface-modified calcium carbonate provides enhanced hydrophobicity, excellent dispersion, and heat stability, making it suitable for breathable film production.

Room Temperature Vulcanizing (RTV) Silicone Sealant

Silane coupling agents surface-modify ultrafine calcium carbonate in RTV single-component silicone sealants. The modified calcium carbonate enhances the sealant, with tensile strength of 0.57 MPa and elongation at maximum strength of 159.60%.

Polyurethane Sealants

Methyl methacrylate (MMA) and silane coupling agent KH570 are co-polymerized to modify calcium carbonate. The modified calcium carbonate has a water contact angle of 60°, sedimentation value of 1.36 ml/g, and good dispersion in polyurethane, improving mechanical properties more than unmodified calcium carbonate.

Silicone Rubber

Nano-calcium carbonate can replace silica in silicone rubber, reducing costs and improving processing. It enhances tensile strength, tear strength, and other mechanical properties. Controlling the crystal form, particle size, and surface treatment improves thixotropic and anti-sagging properties.

Rubber Products

Surface-modified active calcium carbonate reinforces rubber, offering performance comparable to silica. It is used as a reinforcing agent in white, light, and colored rubber products, such as tires, inner tubes, belts, hoses, and shoes, and works well in natural rubber, SBS, and latex, especially improving reinforcement in SBS and coloring.

Natural Rubber Vulcanized Rubber

Resorcinol and hexamethylenetetramine modify calcium carbonate in natural rubber vulcanized rubber. The modified calcium carbonate improves mechanical properties, with a 130% increase in elongation at break, 101% increase in tensile strength, and 70% increase in tear strength compared to unmodified calcium carbonate.

Styrene-Butadiene Rubber (SBR)

Carboxylated polybutadiene (CPB) modifies calcium carbonate as a reinforcing agent for SBR. The vulcanized rubber shows a 60% increase in tensile strength, 70% increase in 300% elongation stress, and 30% increase in tear strength compared to unmodified calcium carbonate.

Semi-Steel Radial Tires Inner Liner

Adding 40 parts of modified calcium carbonates to the inner liner of semi-steel radial tires improves air-tightness, with minimal effect on flexural resistance and processing performance. Factory tests show a 30% improvement in air-tightness, a 3.65 CNY/kg cost reduction, and no impact on high-speed or durability performance.

Paper Fillers

Starch-coated modified calcium carbonate is used as a paper filler. The modified calcium carbonate offers high shear resistance and retention rate, enhancing paper strength and significantly slowing the decline in strength performance.

Reconstituted Tobacco Leaves

Sodium hexametaphosphate and citric acid (1:1 ratio) modify calcium carbonate. The modified calcium carbonate increases ash content in reconstituted tobacco leaves by 8.25% compared to commercial calcium carbonate, with better smoke emissions and sensory results.

Powder Coatings

Modified calcium carbonate serves as a skeleton in powder coatings, increasing film thickness and improving abrasion resistance and durability. Modified calcium carbonate is generally cheaper than other inorganic fillers, reducing coating costs and improving powder yield and spray area.

Latex Paint

Modified nano-calcium carbonate is used to prepare PVC-based latex paint (43% PVC content). The paint with modified nano-calcium carbonate shows improved surface smoothness, density, stain resistance, scrub resistance, and aging resistance. Stearic acid and sodium sulfonate-modified nano-calcium carbonates significantly impact tensile strength, while stearic acid and titanate-modified nano-calcium carbonates improve stain resistance and scrub resistance.

Electrophoretic Paint

Hydrated fluosilicate modifies calcium carbonate, forming a dense thin film with amorphous silica and calcium fluoride. The modification greatly enhances the acid resistance of calcium carbonate, making it suitable for weak acid anode electrophoretic paint.

PVC Car Chassis Anti-Stone Chip Primer

After modification with fatty acids or fatty acid salts, calcium carbonate with a particle size of 40–80 nm is used in PVC car chassis anti-stone chip primer. The modified calcium carbonate provides excellent thixotropy, yield value, and performance.

Ink

Modified calcium carbonates used in ink formulation provides good body and viscosity, excellent printability, fast drying, and no side effects. With small particle size, it shows excellent dispersion, transparency, gloss, opacity, ink absorbency, and drying performance, making prints finer with intact dots. After the wide use of resin binders in inks, modified calcium carbonate has almost replaced other fillers due to its excellent stability.

Toothpaste

A company uses silica-coated micron-sized spherical calcium carbonate particles to surface-modify calcium carbonate as an abrasive in toothpaste. The modified calcium carbonate shows significantly improved compatibility with fluoride, while maintaining the same wear value.

Daily Necessities

Adding active nano-calcium carbonate to cosmetics makes products delicate and smooth. As an additive, it is used in setting powder to eliminate shine, protect skin adhesion, and provide moderate oil absorption and sweat resistance. It is also used in smooth powder, being non-irritating to the skin, with even color and certain coverage.

Artificial Granite

Surface-modified calcium carbonate has low oil absorption and is an important raw material for artificial stone.

Composite Conductive Powder

By coating calcium carbonate, its acid resistance in acidic environments is improved. After combining calcium carbonate with polyaniline to prepare composite conductive powder, it not only provides good conductivity but also overcomes the molding difficulty of pure polyaniline, with broad application prospects.

Lubricating Oil

Modified active nano-calcium carbonate added during the digestion process of lubricating oil reduces the negative impact of surfactants on the oil. It improves the dispersion and stability of nano-calcium carbonate in lubricating oil, enhancing anti-wear and friction-reduction performance.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !