When formulating plastic masterbatches, understanding the difference between talcum and calcium carbonate is crucial for performance and economics. While calcium carbonate (specifically from calcite crystal ore) is the predominant filler used in most masterbatches, talcum powder is also a viable option. A key difference between talcum and calcium carbonate lies in cost, with calcium carbonate being significantly more economical. Furthermore, calcium carbonate offers advantages in the production process as it is generally easier to process than talcum powder.

For polypropylene pellets used in strapping, a mixture of talcum powder and calcium carbonate should be added in the ratio of 70:25:5 (polypropylene: talcum powder: calcium carbonate). For woven bags, calcium carbonate is preferred, with the addition level exceeding 30%. It is important to monitor the temperature during processing.

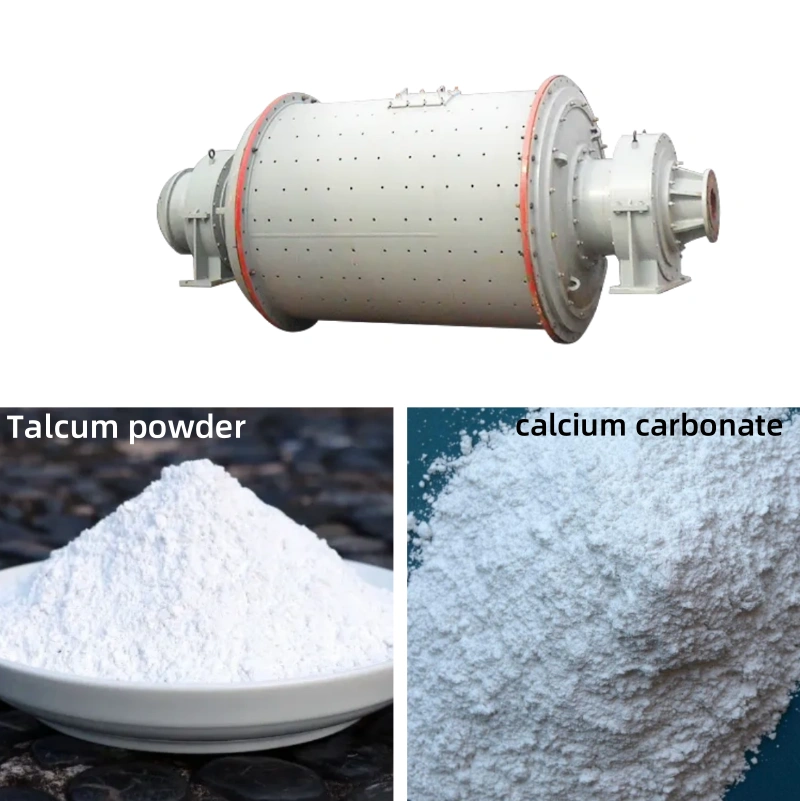

Common Uses of Talcum Powder and Calcium Carbonate as Fillers

The primary purposes of using these fillers include increasing dimensional stability (i.e., reducing shrinkage), enhancing material stiffness, improving heat resistance, and cutting down on material costs. Nevertheless, their use also comes with drawbacks. These include an increase in density, potential reduction in impact toughness if not used properly, and a decrease in material luster.

Particle Size and Selection

Talcum powder, like calcium carbonate, comes in various particle sizes, commonly 300 mesh, 600 mesh, 800 mesh, 1250 mesh, and 2500 mesh, with even finer options available. For plastic applications, 800 – mesh and 1250 – mesh talcum powder often provide the best balance between performance and cost. The price of talcum powder fluctuates, but it can generally be priced according to the mesh number. For example, 800 – mesh talcum powder typically costs between 700 and 850 yuan, while 1250 – mesh powder ranges from 1000 to 1280 yuan. Deviations from these price ranges may indicate abnormal pricing.

Difference Between Talcum Powder and Calcium Carbonate

Shape and Performance:

Talcum powder has a flake – like shape, which endows it with higher rigidity, better dimensional stability, and a higher heat resistance temperature, making it an effective reinforcing agent. In contrast, calcium carbonate is generally granular, resulting in lower stiffness compared to talc. However, its lower cost, high whiteness, and minimal negative impact on plastic impact toughness are its advantages.

Effect on Polypropylene:

Talc has a nucleation effect on polypropylene, whereas calcium carbonate shows no significant such effect.

Origin and Classification:

Calcium carbonate can be broadly categorized into light calcium carbonate and heavy calcium carbonate. In contrast, talcum powder, which is ground from natural minerals, does not have this classification.

Calcium carbonate/talc powder composite reinforced PP, its properties are as follows:

| Content | Tensile strength Mpa | Bending strength Mpa | Flexural modulus Mpa | Rockwell hardness | Model shrinkage% |

| 20% calcium carbonate | 27.8 | 40 | 2000 | 105 | 0.87 |

| 20% talc | 29 | 42 | 1300 | 100 | 0.82 |

| 10% calcium carbonate + 10% talc | 32 | 45 | 2500 | 130 | 0.74 |

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !