Ground calcium carbonate is a powder material made from ores such as calcite, chalk, and marble using mechanical crushing methods. It has a wide range of raw materials, high whiteness, low oil absorption value, good applicability, and low cost. It is one of the most widely used and produced inorganic non-metallic mineral powders. Currently, the production technology of ground calcium carbonate focuses mainly on grinding and surface modification, aiming to produce products with different finenesses suitable for various applications. These include fine powders, ultrafine powders, surface-modified (activated) powders, and fine slurries for paper making.

Heavy Calcium Carbonate Production Process and Equipment

Taking heavy calcium carbonate for the coating industry as an example, its production process includes cleaning, impurity removal, coarse crushing, fine crushing, screening, grinding, classification, material collection, surface treatment, and packaging.

The equipment used includes vibrating conveyors, drum washing machines, hammer crushers, jaw crushers, vibrating screens, impact crushers, grinding mills, classification systems, pulse dust collectors, and packaging equipment.

Ground Calcium Carbonate Grinding Technology and Equipment

Currently, heavy calcium carbonate with d97 ≥ 5μm is mainly produced by dry methods. The equipment includes modified Raymond mills (suspended roller mills or swing mills), roller mills (press roller mills/vertical mills, ring roller mills), and ball mills.

For ultrafine heavy calcium carbonate with d97 < 5μm, dry production processes are generally used. Some processes use wet grinding + drying. Dry production mainly uses ball mills + classifiers, roller mills (with internal classification, vertical/press roller mills), and dry stirred mills + classifiers.

For papermaking-grade ultrafine calcium carbonate slurry with d97 ≤ 5μm, especially d90 ≤ 2μm, wet production is typically used. The main equipment consists of stirred mills and sand mills.

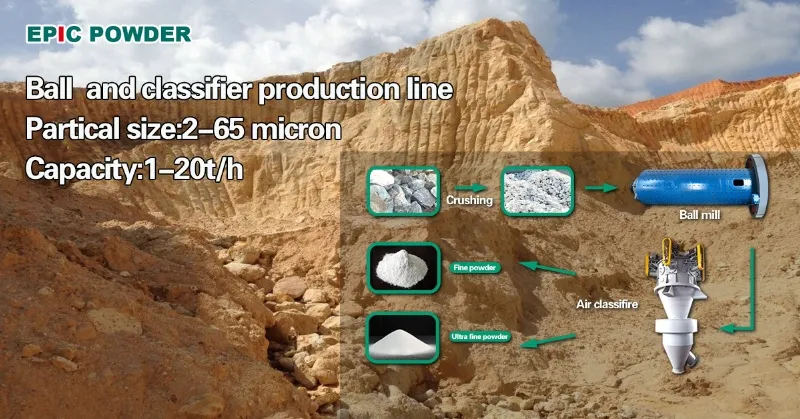

Ball mill + classifier Production Lines

Ball mill + classifier production lines are used to produce heavy calcium carbonate fine and ultrafine powders with d97 = 5–43μm. Features include continuous closed-loop production, multi-stage classification, large circulating loads (300%–500%), and large single-machine production capacities. This production line has been in use since the late 1990s and is one of the main technologies for large-scale ultrafine heavy calcium carbonate production.

Ring Roller Mills

Ring roller mills have been widely used in China for fine and ultrafine grinding of ground calcium carbonate in the past decade. They have the advantages of high grinding ratios and low energy consumption per unit of product. Internal or external fine classifiers can produce ultrafine products with d97 ≤ 10μm. The product fineness can be adjusted between d97 = 5–40μm, with the optimal range being d97 = 10–30μm.

Roller Mills

Roller mills (vertical roller mills/rolling mills) are one of the main large-scale equipment for fine and ultrafine grinding of ground calcium carbonate. They feature a high grinding ratio, and the optimal product fineness range is d97 = 15–45μm. After adding external fine classifiers, ultrafine products with d97 ≤ 10μm can be produced. The products have good particle shapes, low oil absorption values, and are especially suitable for producing fillers for unsaturated polyester composite materials (engineered stone). The energy consumption and wear are also relatively low.

Wet Ultrafine Grinding

Wet ultrafine grinding technology is mainly used to produce papermaking-grade (slurry) products with d90 ≤ 2μm, d97 ≤ 2μm, and ultrafine ground calcium carbonate with d60 ≤ 2μm (which is dried and used as plastic filler). A one-stage or two-stage continuous ultrafine grinding process is typically employed. The main equipment consists of wet stirred mills or sand mills, along with corresponding storage tanks and pumps.

Ground Calcium Carbonate Surface Modification Technology and Equipment

The surface modification of heavy calcium carbonate mainly uses organic coating and composite modification methods.

Organic coating modification uses organic materials. These include stearic acid and its salts, aluminum ester coupling agents, titanium ester coupling agents, and water-soluble polymers. These materials act as surface coating or modifying agents. They coat heavy calcium carbonate powder for modification.

Composite modification uses physical or chemical methods. These methods uniformly mix or coat another inorganic powder. The powder is applied to the surface of heavy calcium carbonate or ultrafine heavy calcium carbonate particles.

Currently, dry modification is the mainstream process for heavy calcium carbonate, except when using wet ultrafine grinding processes. Wet modification is rarely used.

Common surface modification equipment for ground calcium carbonate includes SLG-type continuous powder surface modification machines, HEM high-efficiency coupling modification machines, high-speed heating mixers, vortex mills, and pin mills. Some surface modification of heavy calcium carbonate is done alongside fine or ultrafine grinding. Surface modifying agents are added during the fine and ultrafine grinding process. This is done using the same equipment.

Development Trend of Fine Processing Technology for Ground Calcium Carbonate

Currently, the domestic market for ordinary heavy calcium production capacity has become saturated, and the product price is low with limited technological content and added value. However, the domestic capacity for ultrafine and activated heavy calcium is still insufficient. There is considerable market potential.

Overall, the main development trends of the heavy calcium carbonate industry are large-scale production, functionalization, and automation. This is an inevitable requirement for industrial integration, stabilization, structure optimization, or specialization. It also aims to improve production efficiency, reduce energy consumption, lower production costs, and meet the growing market demand.

Epic Powder

Epic Powder specializes in providing advanced grinding and surface modification equipment for heavy calcium carbonate production. Our state-of-the-art technology ensures high efficiency and precision, offering customized solutions for fine and ultrafine powders. Whether it’s for standard applications or specialized needs, our equipment guarantees consistent product quality and optimal performance, helping our clients meet the growing demand for high-quality calcium carbonate in various industries.