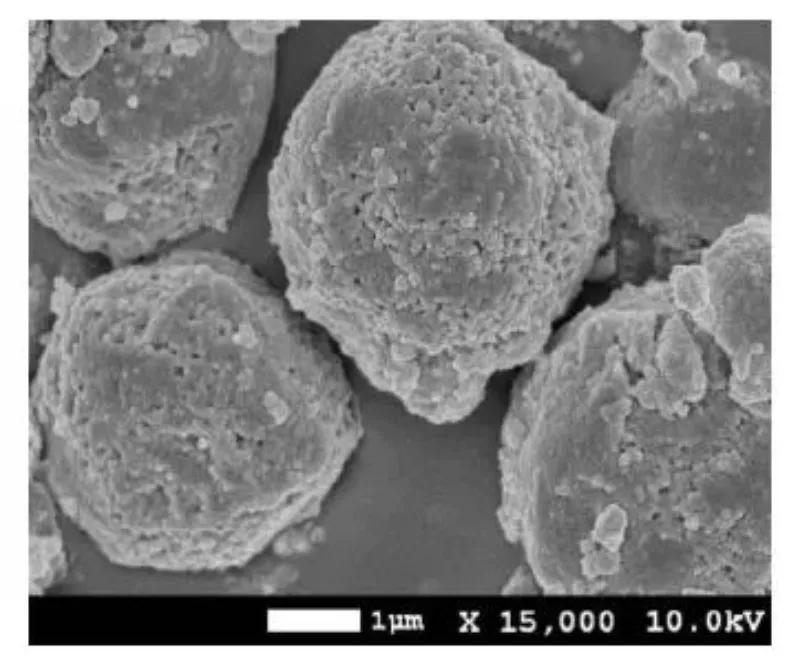

Porous calcium carbonate (CaCO₃) microparticles have gained significant attention due to their wide applications in areas such as chromatography analysis, loading of biological macromolecules, pharmaceutical release, biomimetic minerals, and the construction of superhydrophobic surfaces.

Preparation Techniques for Porous Calcium Carbonate

Template methods have become the mainstream approach for preparing porous calcium carbonate. These methods use surfactants, polymers, and natural plant components as templates. Over time, co-precipitation, emulsion membrane methods, and solvent/hydrothermal methods have been developed, significantly expanding the range of preparation techniques. Among these, the template method is the most commonly used and technologically mature.

The basic principle involves coating the selected template agent with calcium carbonate, forming a core-shell structure. The template is then removed through solvent dissolution, high-temperature calcination, or chemical reactions, leaving hollow particles. Template methods can be divided into soft and hard templates, with soft templates being more commonly used in porous calcium carbonate preparation. Soft template methods often utilize small molecules like surfactants, as well as large organic compounds or polymers as templates.

Porous CaCO₃ produced via soft template methods typically has shapes such as cubic or spherical. Most of these particles have wormhole structures, and the surfaces may be coated with residual template agents or their decomposition products.

Porosity and Morphology Control of Calcium Carbonate

The focus of research on the preparation of porous CaCO₃ particles is on morphology control and nucleation mechanisms. Morphology control is mainly achieved through surfactants, and the production process has a significant impact. A wide variety of surfactants are used, including small molecules like anionic L-aspartic acid and polymeric additives like anionic polystyrene sulfonate (PSS), non-ionic polyethylene glycol (PVA), polyacrylamide (PAM), polyethylene oxide (PEO), and amphiphilic block copolymers (DHBCs). Additionally, complex surfactant systems such as sodium dodecyl sulfate (SDS) and triblock copolymer PEO-PPO-PEO are used in some cases.

Applications of Porous CaCO₃

The applications of porous calcium carbonate mainly depend on its structure and crystal form. As a result, the research into its preparation methods and mechanisms has become a hot topic in its development.

Pharmaceutical Carriers

Porous calcium carbonate can be used as a pharmaceutical carrier material. It has a high pharmaceutical-loading capacity and good pharmaceutical release performance. Particularly, when a responsive shell material is wrapped around the porous CaCO₃, it can prevent sudden pharmaceutical release and enhance the system’s responsiveness, achieving controlled release with multiple responses.

Battery Materials

By loading lithium ions onto CaCO₃, porous calcium carbonate can release lithium ions into the electrolyte as active lithium ions are consumed. This improves the first efficiency and cycle life of lithium batteries. Additionally, nano-calcium carbonate can adsorb by-products like HF in the electrolyte, reducing acidity and prolonging battery life. This lithium loading process is simple, cost-effective, and scalable for widespread use.

Plastic Materials

Porous calcium carbonate has multiple applications in plastics. It serves as a filler to improve the mechanical and optical properties of materials, and as a nucleating agent to enhance processability.

Adsorbent Materials

The high specific surface area and porosity of porous calcium carbonate make it an excellent adsorbent. For example, cellulose-based composite aerogels, combined with porous CaCO₃ and sodium alginate, are effective for formaldehyde adsorption. The prepared aerogels feature numerous mesopores and macropores, achieving a high formaldehyde adsorption capacity of 1105mg/g.

Adhesive Materials

Modified porous calcium carbonate using phenylsilane coupling agents can load curing agents in amounts of 18–30 parts. This high curing agent load provides strong adhesion and solvent resistance, especially suitable for bonding polyimide films and metal meshes to prepare screen printing plates.

Paper-based Decorative Materials

Porous calcium carbonate loaded with titanium dioxide has been successfully used to prepare paper-based decorative materials with excellent UV resistance.

Biosensors

Biosensors offer fast, trace-level analysis at the molecular level. They are widely used in clinical diagnostics, industrial control, food and pharmaceutical analysis, environmental protection, and biotechnology research.

Asphalt Pavement Additives

Additives for asphalt pavement materials, including self-repairing asphalt, are made by blending silver nanowire-modified microcapsules, asphalt rejuvenators, and porous calcium carbonate. These additives slowly release rejuvenators to replenish lost aromatic components in asphalt, delaying aging and cracking. This combination significantly improves the durability and self-repair ability of asphalt roads.

Bioceramics

Calcium carbonate is widely used in biology and medicine due to its excellent osteoconductivity, biocompatibility, and degradability. Porous calcium carbonate, with good porosity, pore size, and connectivity, offers better biocompatibility than conventional materials, aiding bone regeneration and repair. In clinical applications, it is used for bone defect repair in orthopedics and oral and maxillofacial surgery with excellent outcomes.

Conclusion

Porous calcium carbonate continues to attract significant attention due to its diverse applications in fields such as pharmaceutical delivery, battery materials, and biocompatible ceramics. As preparation techniques improve, the material’s versatility in industrial and environmental applications expands. With its excellent porosity, surface area, and functional properties, porous CaCO₃ is poised to play a pivotal role in advancing technology across multiple sectors.