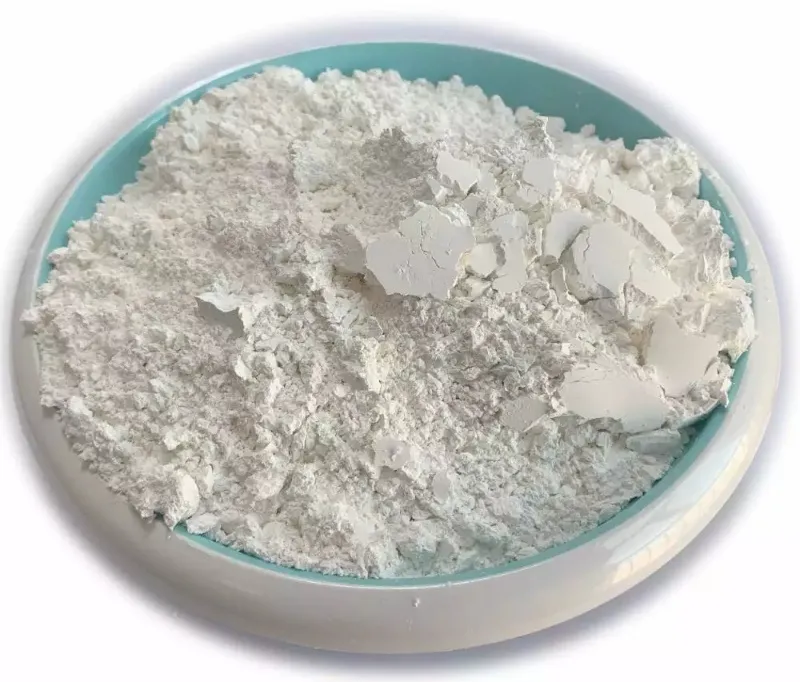

According to different production methods, calcium carbonate can be classified into ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), colloidal calcium carbonate, and crystalline calcium carbonate. Among these, GCC is produced through direct mechanical grinding. Ultra-fine calcium carbonate is an essential non-metallic mineral raw material, widely used due to its abundance, low cost, and performance-enhancing properties. It can improve product quality and shelf life while reducing production costs, making it indispensable in many industries.

| Type | Preparation Method |

|---|---|

| Ground Calcium Carbonate (GCC) | Produced by mechanically grinding natural calcite, limestone, chalk, or shells using ball mills or high-pressure mills. |

| Light (Precipitated) Calcium Carbonate (PCC) | Also known as precipitated calcium carbonate. Limestone is calcined to produce lime and CO₂. The lime is then slaked with water to form lime milk, which reacts with CO₂ to generate calcium carbonate precipitate. After dehydration, drying, and pulverization, PCC is obtained. |

| Colloidal Calcium Carbonate (Activated/Modified Calcium Carbonate) | Also called surface-treated or activated calcium carbonate (“White Yanhua”), prepared by surface modification of GCC or PCC using suitable coupling agents. |

| Crystalline Calcium Carbonate | Produced by reacting calcium hydroxide with hydrochloric acid to form calcium chloride, followed by purification, decolorization with activated carbon, and carbonation in the presence of ammonia and CO₂ to form crystalline calcium carbonate, which is then crystallized, filtered, washed, dried, and sieved. |

Industrial Grades of Ultra-fine Calcium Carbonate

Industrial calcium carbonate is typically classified by average particle size into five grades:

- Granular calcium carbonate: >5 μm

- Micropowder calcium carbonate: 1–5 μm

- Fine calcium carbonate: 0.1–1 μm

- Ultrafine calcium carbonate: 20–100 nm

- Superfine calcium carbonate: <20 nm (commonly referred to as nano calcium carbonate).

Production Methods of Ultra-fine Calcium Carbonate

- Batch bubbling carbonation method

- Continuous bubbling carbonation method

- Continuous spray carbonation method

- Supergravity reaction crystallization method

Application Fields

Rubber Industry

Main functions:

- Increase product volume and reduce natural rubber usage, lowering costs.

- Improve processing performance.

- Enhance tensile strength, tear resistance, compression set, and flex resistance compared to regular calcium carbonate.

- Provide reinforcing and whitening effects, enabling transparent or translucent rubber products.

Application requirements:

- Micron-grade calcium carbonate serves as a non-functional filler.

- Ultrafine active calcium carbonate (30–80 nm) disperses evenly, providing strong reinforcement.

- When particle size <20 nm, its reinforcing performance rivals that of silica.

- Often used synergistically with carbon black or silica fillers.

Plastics Industry

Main functions:

- Increase volume and reduce costs.

- Improve stability, hardness, and rigidity.

- Enhance processing flow, heat resistance, gloss, and impact strength.

- Improve dispersion and reduce friction.

Application requirements:

- Oil absorption must be controlled; excessive absorption affects plasticizer efficiency.

- Proper surface treatment and activation are required to prevent agglomeration.

- Dosage varies with polymer type and product performance, up to 40% in some formulations.

Ink Industry

Main functions:

- Adjust dispersion, transparency, gloss, opacity, and absorption properties.

- High whiteness allows partial replacement of expensive titanium dioxide.

Application requirements:

- High-performance, surface-modified ultrafine calcium carbonate with spherical or cubic morphology is preferred.

Coatings Industry

Main functions:

- Improve whiteness, gloss, and opacity.

- Reduce cost by partially or completely replacing titanium dioxide.

- Provide reinforcement and enhance rheology.

- Ultrafine calcium carbonate (<80 nm) improves thixotropy, suitable for automotive chassis and topcoat formulations.

Application requirements:

- Strict control of particle size and surface area according to formulation needs.

Adhesives and Sealants

Surface-treated GCC with stearic acid exhibits strong hydrophobicity and low moisture content.

Benefits include:

- Enhanced storage stability and reduced premature curing.

- Lower oil absorption, allowing higher filler loading.

- Improved dispersion in polymer matrices.

Paper Industry

In papermaking, calcium carbonate serves as both filler and coating pigment in alkaline papermaking processes.

Currently, fine calcium carbonate is dominant, while ultrafine calcium carbonate is increasingly used in high-grade specialty papers, representing a key future growth direction.

Health Food and Feed Industry

When toxic elements such as lead and arsenic are strictly controlled, ultrafine calcium carbonate can be used as a dietary calcium source additive.

It is inexpensive, easily absorbed, and already applied in products like milk powder and animal feed supplements.

Daily Chemical and Pharmaceutical Applications

Used as a filler in cosmetics, soaps, facial cleansers, and toothpaste.

In pharmaceuticals, ultrafine calcium carbonate serves as a buffer and calcium source in microbial fermentation for antibiotics and other products, and also plays a pharmacological role in antacids and pain relief formulations.

Drilling Fluid Control

Ultrafine calcium carbonate can adjust drilling fluid properties such as pH, viscosity, and density.

It helps reduce cement slurry retention, enhances lubrication, filling, gelation, and overall control of drilling fluid characteristics — leading to improved drilling performance.

Epic Powder

Ultrafine calcium carbonate is a key functional filler widely used in rubber, plastics, coatings, and paper industries for its excellent reinforcement and cost advantages. With the growing demand for high-performance and eco-friendly materials, its market potential remains strong.

Epic Powder provides advanced grinding, classification, and surface modification solutions for ultrafine calcium carbonate, ensuring precise particle control, high dispersion, and stable quality to help customers achieve superior performance.