Q: What is Calcium Carbonate Modification? Why is Modification Necessary?

A: Calcium carbonate modification refers to altering the surface properties of calcium carbonate particles using physical or chemical methods. This process improves their performance in various applications. Calcium carbonate is widely used in plastics, rubber, coatings, and other industries. However, it faces several issues that need to be addressed through modification:

- Improving dispersibility: Ultrafine calcium carbonate has high surface energy and tends to agglomerate. Modification helps disperse it evenly in the matrix.

- Enhancing compatibility: Calcium carbonate is hydrophilic, while polymers are often hydrophobic. Modification can improve the interface bonding.

- Reducing oil absorption: Modification reduces voids between particles, making the packing denser and lowering oil absorption.

- Expanding application fields: Modified calcium carbonate can be used in high-end applications like breathable membranes and sealants.

- Imparting functional properties: Modification can give calcium carbonate special functions, such as antibacterial and flame-retardant properties.

Q: What are the Main Methods of Calcium Carbonate Modification?

A: The main modification methods for calcium carbonate are:

- Inorganic surface treatment: Hydrolyzing silicon fluoride ions precipitates amorphous silica on the surface of calcium carbonate. This improves acid resistance, lowers pH, and enhances hydrophilicity and dispersibility.

- Organic surface modification: The most common method, where organic modifiers are applied to coat calcium carbonate surfaces. Common modifiers include:

- Fatty acids (salts)

- Phosphate esters

- Quaternary ammonium salts

- Silane coupling agents

- Titanium ester coupling agents

- Aluminum ester coupling agents

- Composite coupling agents

- Polymer surface modification: Forms a core-shell structure on the calcium carbonate surface by polymerizing monomers or adsorbing polymer solutions and removing the solvent. This method reduces aggregation and improves dispersibility.

- Mechanical-chemical modification: Mechanical forces activate the calcium carbonate surface, changing its crystal structure and enhancing reactivity. This is suitable for larger calcium carbonate particles and promotes polymerization on the surface.

Q: What are the Main Processes for Calcium Carbonate Modification?

A: The main modification processes for calcium carbonate are divided into three categories:

| Process Type | Characteristics | Suitable Applications | Pros & Cons |

| Dry modification | Directly mixing calcium carbonate and modifiers | Coupling agent modification | Simple process, low equipment investment, but poor modification effect and high pollution. |

| Wet modification | Adding modifiers to a slurry and stirring | Light/nano calcium carbonate | Even modification, good effect, but complex process. |

| In-situ modification | Simultaneous preparation and modification | Special functional requirements | Strong bonding between particles and modifiers, but difficult process control. |

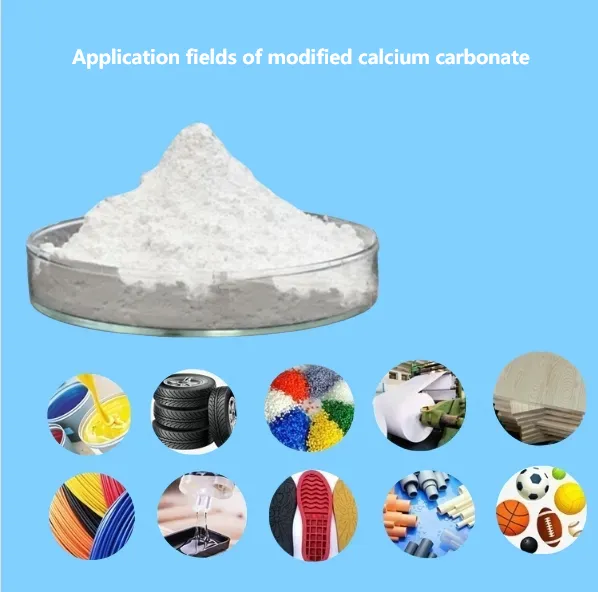

Q: In Which Fields is Modified Calcium Carbonate Important?

A: Modified calcium carbonate has wide applications in various industrial fields, including:

- Plastic industry:

- PVC: Increases tensile strength and elongation, improves processing performance.

- PP: Reduces the decline in tensile strength, increases impact strength.

- HDPE: Enhances friction resistance, best performance with 8phr loading.

- LDPE: Best performance of composite materials with 10% modified calcium carbonate.

- ABS: Increases impact strength, tensile strength, and heat distortion temperature.

- Rubber industry: As a filler, it increases the volume of products, reduces costs, and improves processing and mechanical properties.

- Coating industry:

- Improves film adhesion by over 20%.

- Reduces gloss.

- Increases impact strength.

- Paper industry: Used as a filler to improve paper smoothness, opacity, and whiteness; as a coating pigment, it improves printability.

- Construction materials:

- Key raw material in cement production.

- Filler in building coatings.

- Raw material for artificial marble and tiles.

Q: What Significant Advantages does Calcium Carbonate Modification Bring?

A: Modified calcium carbonate offers numerous advantages:

- Environmental benefits:

- Saves petroleum resources: Filling 30% calcium carbonate in PE saves 900,000 tons of petroleum-based resin annually.

- Promotes plastic combustion: The burning time of polyethylene film containing 30% calcium carbonate decreases from 12 seconds to 4 seconds.

- Reduces toxic smoke emissions: Absorbs acidic gases, reducing the likelihood of acid rain.

- Performance improvements:

- Increases rigidity: Improves bending strength, modulus, hardness, and wear resistance.

- Enhances dimensional stability: Reduces shrinkage, warping, and creep.

- Improves heat resistance: Absorbs substances that promote decomposition, improving thermal stability.

- Enhances tear resistance: Increases the isotropy of composite materials.

- Economic benefits:

- Reduces production costs: Calcium carbonate is cheaper than polymer-based materials.

- Increases market competitiveness: Offers significant cost-performance advantages.

- Good processing performance: Improved flowability, easy molding, and increased production efficiency.

Q: What are the Latest Trends in Calcium Carbonate Modification?

A: Although limited information is available on the latest research advances, the following trends are evident from existing data:

- Functionalization and specialization: Development of specialty modified calcium carbonate for specific applications.

- Ultrafine modification: Ultrafine heavy calcium carbonate with a particle size of ≤5μm is encouraged.

- Nanomaterials: Nano-calcium carbonate (1-100nm) shows advantages in reinforcement and dispersibility.

- Composite modification technologies: Combining multiple modification methods, such as “amphiphilic” surface treatment technologies.

- Green and eco-friendly processes: Development of low-toxicity, high-efficiency modifiers, such as aluminum ester coupling agents.

Epic Powder

Epic Powder specializes in delivering tailored calcium carbonate solutions that meet the most demanding industrial requirements. Our expertise in dry/wet modification and functionalization ensures optimal performance for your specific applications. Contact us to discover how our innovative powder solutions can elevate your products.