Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made

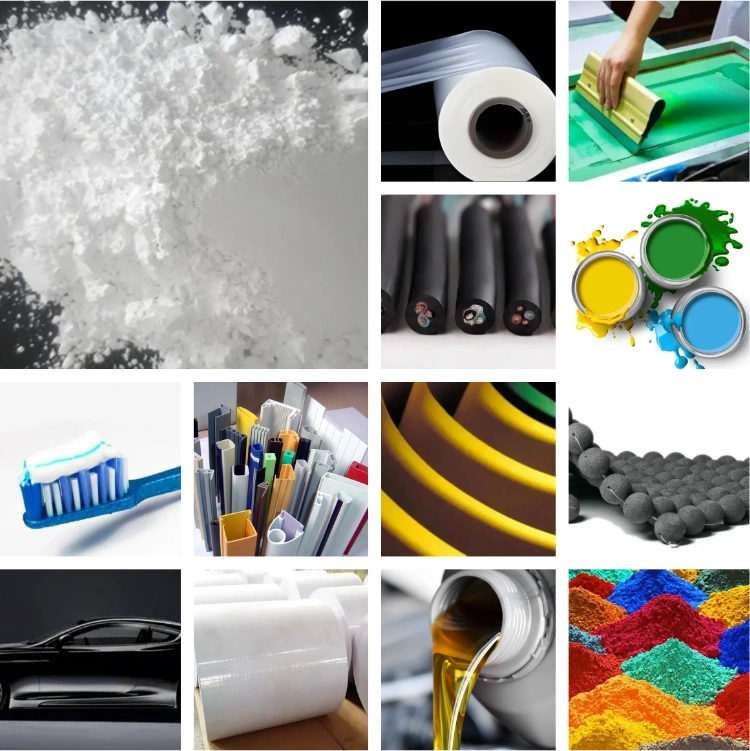

Calcium carbonate (CaCO₃) is a widely used inorganic non-metallic material, extensively applied in plastics, paper, coatings, rubber, and many other industries. Its performance—particularly in terms of particle size and morphology—depends almost entirely on one crucial stage: grinding. This Q&A aims to explore the necessity, key equipment, and technologies involved in calcium carbonate grinding. Q1: Why […]

Calcium Carbonate Grinding Equipment: How the “White Gold” of Modern Industry Is Made Read More »