Calcium carbonate is an inorganic compound with the chemical formula CaCO₃. It is commonly known as limestone, limestone, stone powder, marble, etc. It is alkaline, basically insoluble in water, and easily soluble in hydrochloric acid. It is one of the most common substances on earth and exists in rocks such as aragonite, calcite, limestone, marble, and travertine. It is also the main component of animal bones or shells. It is an important building material and has a wide range of uses in industry.

Calcium carbonate is everywhere in our daily lives. Calcite crystals, marble tiles, and fireproof ceilings. The full, rich, and distinct-colored pearls, as well as various-shaped seashells and eggshells, are mainly composed of CaCO₃.

Classification

Light calcium carbonate

Commonly known as light calcium, it is a powdered material produced from limestone.

It is made through processes such as calcination, digestion, carbonation, dehydration, drying, and grading. Light CaCO₃ has reached a development plateau. Product upgrading, technological innovation, and energy conservation are now the focus for industry growth. In the future, the focus will be on developing fine, functional, and specialized products. These products will have high demand, technological content, and added value.

Heavy calcium carbonate

Commonly known as heavy calcium, it is a powdered material produced by mechanically grinding natural minerals such as calcite, marble, limestone, chalk, and white jade.

Ultrafine and reactive heavy calcium still have significant market potential. High-quality ultrafine heavy calcium can replace some higher-priced light calcium or even nano-calcium in certain fields. It can also be blended with ultrafine heavy calcium during the production of light calcium or nano-calcium to reduce production costs, improve product quality, broaden application areas, and lower energy consumption and carbon dioxide emissions.

Nano Calcium Carbonate

Nano calcium carbonate is an ultrafine solid powder material developed in the 1980s. Its particle size ranges from 0.01 to 0.1 μm. It is mainly used in high-end rubber and plastic products, papermaking, silicone adhesives, automotive chassis paints, inks, and more.

Its performance generally reaches world-class standards. As a high-end product in the CaCO₃ series, it is expected to gradually replace ordinary CaCO₃. It has a promising market outlook. The annual demand growth rate for nano CaCO₃ in China is expected to be 5% to 10% in the coming years.

.

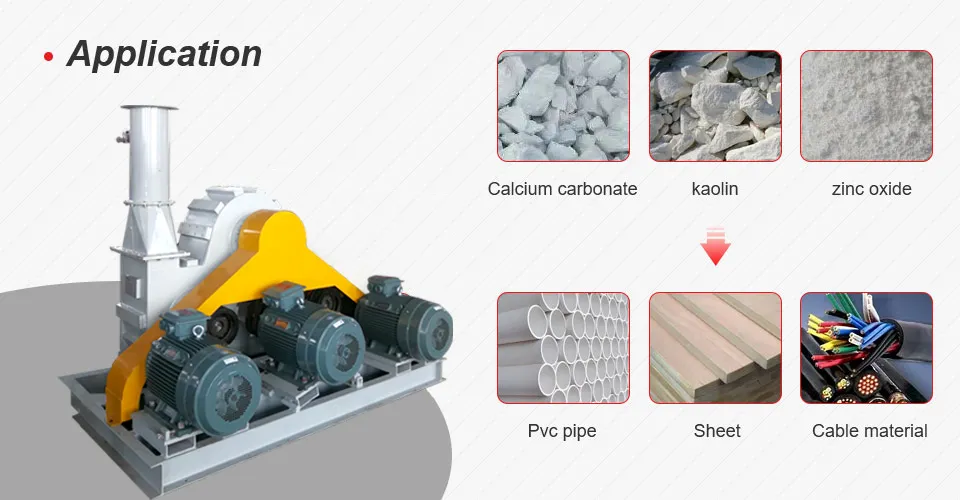

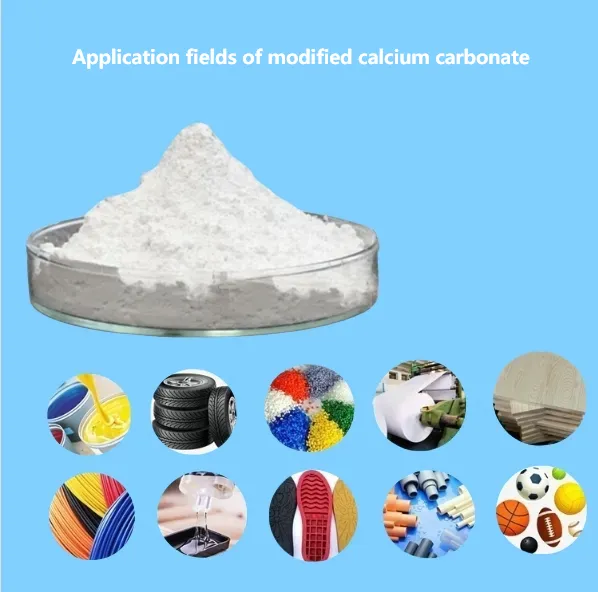

Application

Application of calcium carbonate in papermaking industry:

The paper industry is the largest application field for CaCO₃, with annual consumption exceeding 10 million tons. It is used to replace wood pulp and other pigments, improving paper brightness, opacity, porosity, bulk density, and other properties.

Application of calcium carbonate in coating industry:

Calcium carbonate has high whiteness and low oil absorption, which can reduce the amount of emulsions required. This not only lowers the cost of latex paints but also serves as a structural filler, improving coating thickness, hardness, and wear resistance. Meanwhile, ultrafine heavy CaCO₃ has strong spatial barrier capabilities. When used in coatings, it can enhance the covering power of titanium dioxide, reducing the amount of titanium dioxide needed.

Application of calcium carbonate in plastics industry:

Calcium carbonate is inexpensive and, when added to plastic products, can enhance whiteness. It helps improve the dimensional stability, rigidity, and rheology of plastic products, while also improving the processing performance of plastics.

Application of calcium carbonate in rubber industry:

Calcium carbonate filled in rubber can increase product volume, saving expensive rubber and reducing costs. Additionally, heavy CaCO₃ in rubber provides higher tear strength, tensile strength, and wear resistance than pure rubber. It significantly reduces vulcanization time and adjusts viscosity, making it a high-quality, non-toxic, and environmentally friendly material.

Conclusion

With the economy focusing on high-quality and healthy development, demand for high-end CaCO₃ products will surge in plastics, rubber, coatings, and papermaking. The CaCO₃ industry will have strong growth prospects for a long time. The development of high-grade nano CaCO₃, ultrafine calcium carbonate, and medical and food-grade products will accelerate.

Functional and specialized CaCO₃ products will be the future development direction. Additionally, developing new surfactants to improve CaCO₃ powder properties is a critical challenge.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !