Calcium carbonate (CaCO₃) is one of the most versatile and widely used minerals in the world. It is commonly found in nature as three distinct forms: calcite, marble, and limestone. Each of these materials has unique characteristics that determine their suitability for different industrial applications. This article delves into the differences between these three types of calcium carbonate, highlighting their physical properties, composition, and diverse uses across different industries.

Comparison of Three Types of Calcium Carbonate

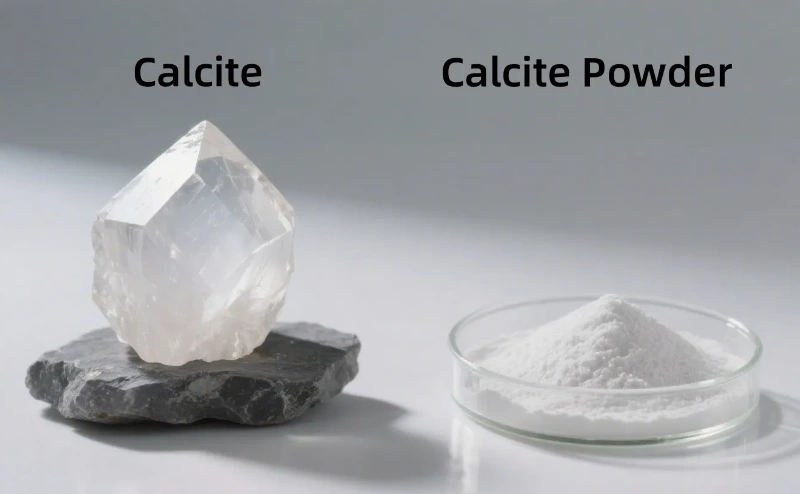

Calcite

Calcite is a mineral that exhibits clear cleavage, with a transparent appearance and a smooth surface that remains intact even after crushing. It is abundant in nature, and calcite deposits can be found across many regions worldwide. Calcite is categorized into two types: large calcite and small calcite. Large calcite has clear, regular cleavage, with a high degree of transparency, while small calcite displays irregular, dense cleavage. Calcite typically comes in three hues: milky white, yellowish, and reddish, with variations depending on the production region. These color differences can impact the optical properties when processed into heavy calcium carbonate powder. The calcium content of calcite is typically above 99%, with impurities mainly composed of metals like Fe, Mn, and Cu. The relative density of calcite ranges from 2.5 to 2.9 g/cm³, and it has a Mohs hardness of 2.7–3.0.

Marble

Marble, also known as dolomite rock, is a metamorphic rock formed from the recrystallization of limestone. It is primarily composed of calcite, limestone, serpentine, and dolomite, with the carbonate component accounting for more than 95%. The Mohs hardness of marble ranges from 2.5 to 5, and its density varies between 2.6 and 2.8 g/cm³. Marble deposits are divided into coarse-grained and fine-grained types. Coarse-grained marble displays large, cube-shaped crystals, while fine-grained varieties have much smaller crystals. Marble tends to have a bluish-white color, but impurity contents, such as magnesium oxide (0.2–0.7%), ferric oxide (<0.08%), and manganese (1–50 mg/kg), vary by region.

Limestone

Limestone is primarily composed of calcite and aragonite. Both crystalline forms of calcium carbonate, and sometimes contains small amounts of dolomite, siderite, quartz, feldspar, and clay minerals that influence the color. It is a fine-grained or cryptocrystalline rock, typically found in white and gray colors. Limestone has a calcium carbonate content greater than 95%, with impurities such as silica, alumina, iron oxide, magnesium, and strontium. The Mohs hardness of limestone is between 3.5 and 4, and its density is around 2.7 g/cm³.

Differences in Uses of Calcite, Marble, and Limestone

Plastics

Both calcite and marble are widely used in plastics, although there are differences in color and crystal structure between the two. The crystalline structure affects the color, tensile strength, and impact resistance of plastic products. Calcite, which belongs to the hexagonal crystal system, tends to have larger length-to-diameter ratios, making it more suitable for producing plastics with better toughness and impact resistance. In contrast, marble crystals are typically cube-shaped and have smaller length-to-diameter ratios, resulting in products with less toughness and more brittleness. Therefore, when used in the same formula, marble powder generally produces more brittle products compared to calcite powder.

Paper

In papermaking, the softer and lower-hardness nature of both calcite and marble makes them ideal as fillers. These materials result in lower wear rates on equipment and help extend the life of machinery parts, such as filter screens and cutting heads. This is particularly beneficial for papermakers looking to reduce maintenance costs and improve the efficiency of their production lines.

Latex Paint

Calcium carbonate raw materials vary in purity, and calcite typically has a higher purity than marble. Calcite’s calcium carbonate content often exceeds 96%, with lower levels of impurities such as magnesium oxide and ferric oxide. This purity ensures that latex paints made with calcite are more stable and have better quality than those made with marble-based fillers.

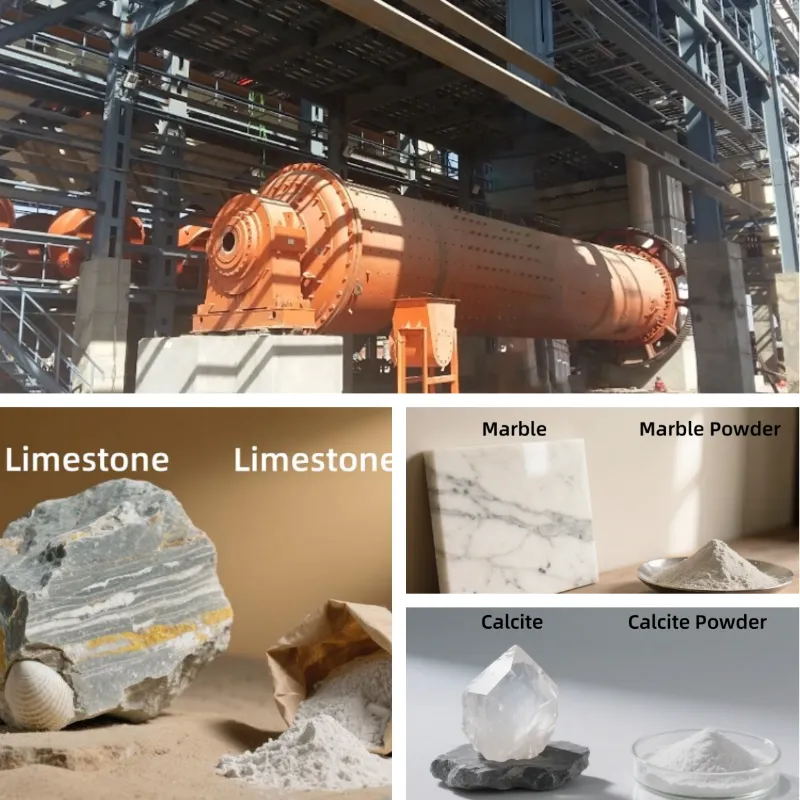

Epic Powder

Epic Powder specializes in advanced grinding equipment, which is essential for optimizing the deep processing of calcite, marble, and limestone. With over 20 years of expertise in the powder processing industry, Epic Powder provides high-performance grinding equipment such as ball mills, air classifier mills, and surface modification equipment are particularly useful for processing calcium carbonate into ultra-fine powders with specific particle sizes and shapes, enhancing their performance in applications like plastics, coatings, and paper. By using the right grinding and classification technologies, Epic Powder helps customers optimize product quality, reduce processing costs, and expand the application range of calcium carbonate in industries worldwide.