Heavy calcium carbonate powder is a typical low-carbon, environmentally friendly inorganic non-metallic mineral material. It is one of the important fillers for breathable membranes. In the preparation of breathable membranes, heavy calcium powder acts as a “porogen.” Through unidirectional or biaxial stretching, polyester matrix and heavy calcium particles separate. Micro-channels are formed between the filler particles, creating a microporous breathable membrane. This membrane allows water vapor diffusion while blocking liquid water leakage. Currently, the fineness of heavy calcium powder (d97) and its distribution, as well as the content of 2 µm fine powder, directly impact the flowability of the powder/resin processing. These factors also affect the production stability of the breathable membrane. They have a crucial impact on the membrane’s stretching, pore structure, air permeability, and mechanical properties. Therefore, this article focuses on grinding and classification key technologies. It is related to the fineness (d97) and 2 µm fine powder content.

Status Quo

The application of domestic heavy calcium in breathable membranes and other membrane products mainly presents the following characteristics:

- The fluctuation range of d97 fineness is large, which can cause instability in the quality of breathable membranes. Especially when particles with larger particle size are in the polymer matrix, they will become stress concentration points. This will affect the performance of the product and even make downstream processing impossible;.

- The content of 2 µm fine powder, whether too much or too little, especially when excessive, can lead to powder agglomeration, forming pseudo-large particles. This makes the powder difficult to disperse, affecting the stability of the breathable membrane production process and its performance.

- According to sampling analysis, a foreign calcium carbonate company’s membrane-specific heavy calcium powder was studied. The powder fineness d97 is 16.5~17.3 µm. The fineness fluctuation is ≤1 µm. The content of 2 µm fine powder is 29.1%~30.3%. The particle morphology is approximately spherical or spindle-shaped. This product has strong market competitiveness.

Grinding Process

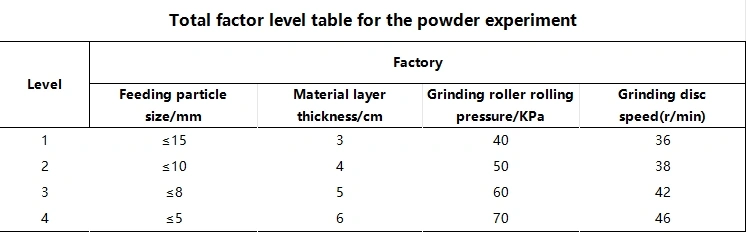

This experiment focuses on four process parameters directly related to the grinding process: disk speed, roller pressure, feed particle size, and material layer thickness. The content of 10 µm fine powder in the ground powder is used as the evaluation criterion. Based on model construction and preliminary field experiment parameters, the level ranges for each factor are set as shown in the table.

Classifying and Steady Flow Process

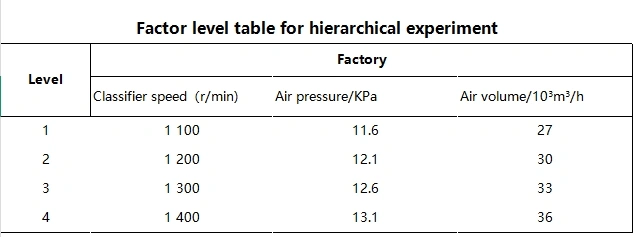

According to the previous classification, air volume and pressure test parameters and flow field model simulation, the classifier rotor speed, air volume and pressure are determined as the factor levels of the classification experiment. The classification process level is shown in the table. The finished powder fineness d97=17±0.5 µm and the 2 µm fine powder content in the powder are used as the evaluation basis.

Industrial Production and Application

The disk speed was set to 42 r/min, with a feed particle size not exceeding 8 mm, a material layer thickness of 6 cm, and a roller pressure of 60 kPa.

The classifier rotor speed was set to 1400 r/min, air pressure to 12.1 kPa, and air volume to 2.7×10⁴ m³/h, and these parameters were set as the system operating parameters. After conducting three continuous 12-hour system runs on-site, the results showed that:

- The product fineness d97 ranged from 16.53 to 17.32 µm.

- The content of 2 µm fine powder was between 28.9% and 30.3%.

These results met the foreign product specifications of d97 = 17±0.5 µm and 2 µm fine powder content of 28-31%, and the performance was better than similar domestic products.

Conclusion

Through the experimental investigation of the grinding and classification steady-flow process, real-time monitoring of equipment parameters and particle size detection, and process parameter simulation, the steady-flow process parameters for the finished powder were determined as follows:

The optimal grinding parameters were:

- Disk speed: 42 r/min

- Feed particle size: ≤8 mm

- Material layer thickness: 6 cm

- Roller pressure: 60 kPa

The results from the orthogonal experiment were consistent with the previous experimental predictions.

The optimal classification parameters were:

- Classifier rotor speed: 1400 r/min

- Air pressure: 12.1 kPa

- Air volume: 2.7×10⁴ m³/h

Comparison with the orthogonal experiment results showed that the classification effect and the predicted finished powder qualification rate were consistent.

Through the above experimental research on process parameters, energy-efficient and high-efficiency production of heavy calcium carbonate powder for breathable membranes was achieved.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !