There are many types of ground calcium carbonate grinding and processing equipment. They are combined with ultra-fine grade machines to create an ultra-fine processing system. This system generally achieves the desired effect of ultra-fine production. Currently, the mainstream demand for heavy calcium products is between 600 and 1500 mesh. Compared to talc, barite, and kaolin, the value-added rate of heavy calcium is relatively low. Scale is one of the main factors affecting the profitability of heavy calcium products.

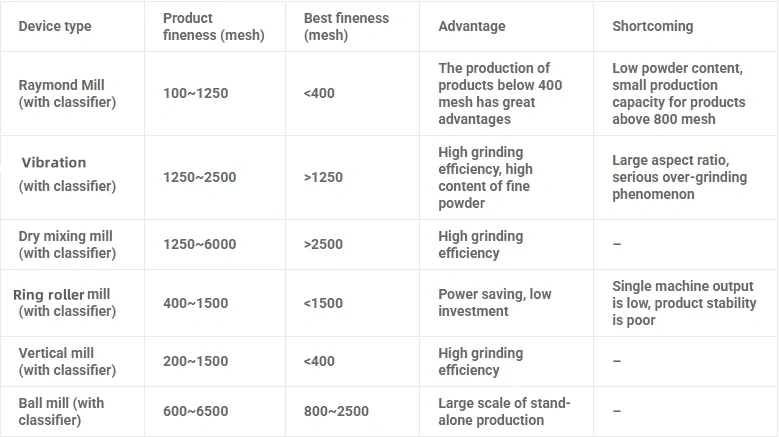

Ground calcium carbonate ultra-fine processing equipment is divided into grinding equipment and grading equipment. The grinding equipment includes Raymond mill, vibration mill, and dry stirring mill. It also includes ring roller mill, vertical mill, and ball mill. Additionally, the impeller-type ultra-fine grade machine adopts forced eddy current. Fine classification systems are crucial for achieving consistent product quality. Precision control is also important for maintaining the desired particle size distribution. As technology advances, new materials and processing methods are being explored. These innovations aim to enhance the performance and efficiency of heavy calcium processing systems.

Comparison of various types of ultra-fine processing equipment

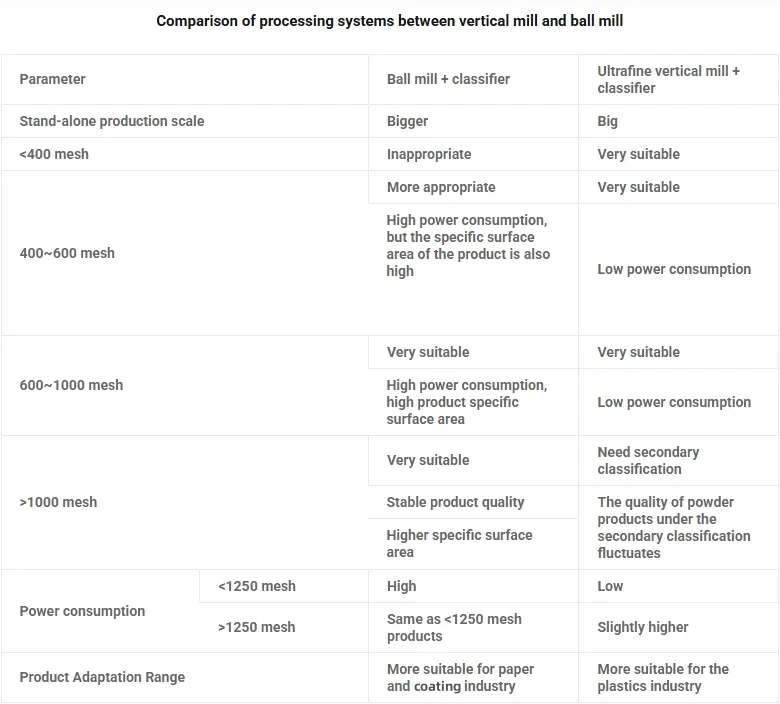

Comparison of processing systems between vertical mill and ball mill

The vertical mill is used to produce heavy calcium. The fineness of the milled product is generally below 1000 mesh. Under secondary classification, the powder quality may fluctuate. This fluctuation often results in a lower-grade product. The variation in fineness can impact product consistency and performance. If 1250 mesh is produced The above products must be classified twice. Similarly, the secondary classification of 800-mesh powder produced by the vertical mill results in different particle size distributions of the two lower products, which makes it difficult to define the quality of the lower products.

The use of ball mills and large classifiers makes it possible to produce single-machine heavy calcium on a large scale. The single-machine capacity of the ball mill is the largest, and its performance is more prominent when producing products with more than 1250 mesh. The superfine vertical mill has obvious energy saving effect when producing 400~1000 mesh heavy calcium products. The production of large classifiers has been very mature and reliable, producing ground calcium carbonate powder below 2500 mesh, which greatly reduces investment costs and maintenance costs. The combined use of multiple large classifiers is an effective way to diversify products at the same time. The demand for ultrafine heavy calcium powder below 2μm is increasing rapidly, and the research on large-scale sub-micron classifiers is the main task at present.

Conclusion

In conclusion, the combination of ground calcium carbonate and advanced superfine processing equipment significantly enhances product quality and performance. By achieving finer particle sizes and better control over material properties, this technology supports a wide range of industries, from plastics to paints, ensuring efficient production and improved product characteristics.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !