Calcium carbonate powders, commonly known as limestone or stone powders, is primarily composed of calcium carbonate. It is slightly alkaline, insoluble in water, and soluble in acids.

It is one of the most common substances on Earth, found in rocks such as aragonite, calcite, chalk, limestone, marble, and travertine. It is also a major component of animal bones and shells.

Calcium carbonate powders can be categorized into: heavy calcium powder, light calcium powder, activated calcium powder, flue gas desulfurization calcium powder, and ultrafine calcium carbonate.

Main Uses of Calcium Carbonate Powder

Rubber Industry

Calcium carbonate powder (400 mesh, whiteness: 93%, calcium content: 96%) is one of the most widely used fillers in the rubber industry. It is used to increase the volume of rubber products and reduce the amount of expensive natural rubber, thus lowering costs. Adding calcium carbonate powder to rubber improves tensile strength, tear strength, and wear resistance compared to pure rubber vulcanizates.

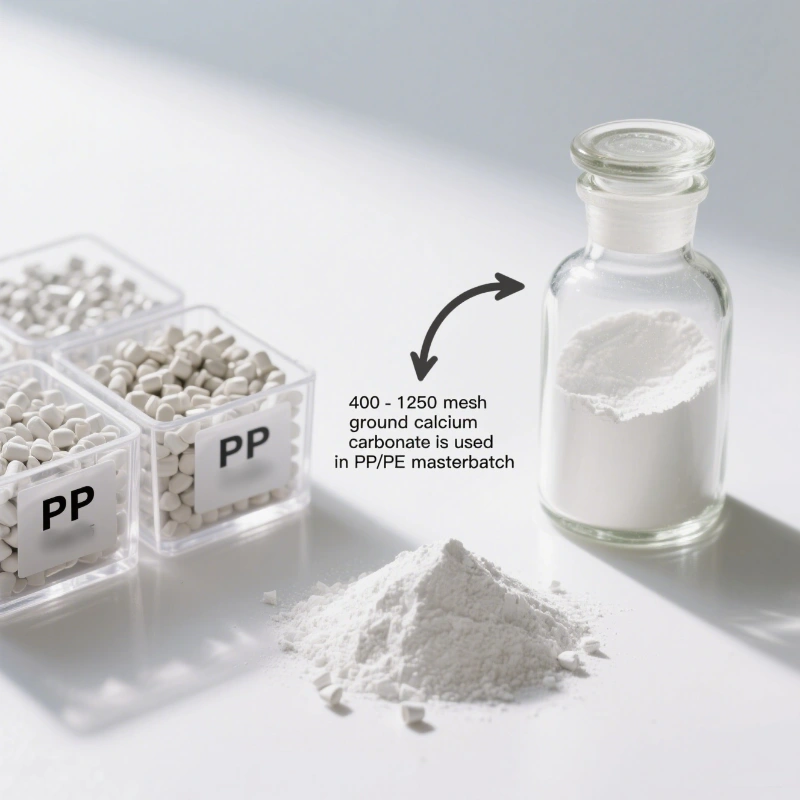

Plastic Industry

In plastic masterbatches and color concentrates (400 mesh, whiteness: 95%, calcium content: 99%), calcium carbonate serves as a skeleton material. It stabilizes the dimensions of plastic products, increases hardness, and enhances surface gloss and smoothness. Its whiteness (over 90) also allows it to replace expensive white pigments.

Paint Industry

Calcium carbonate powder for paints and latex paints (800–1000 mesh, whiteness: 95%, calcium content: 96%) is widely used, with a typical usage of 30% or more in thick paints.

Water-based Coatings

Calcium carbonate powder (800–1000 mesh, whiteness: 95%, calcium content: 96%) is commonly used in water-based coatings, improving properties such as non-settling, easy dispersion, and good gloss. It is typically used in amounts of 20-60%.

Paper Industry

Heavy calcium powder (325 mesh, whiteness: 95%, calcium content: 98%) plays a significant role in the paper industry, ensuring paper strength and whiteness at a lower cost.

Construction Industry

Calcium powder for dry mortar (325 mesh, whiteness: 95%, calcium content: 98%) is important in concrete production, lowering production costs while increasing product toughness and strength.

Fireproof Ceiling Industry

Calcium powder for fireproof ceilings (600 mesh, whiteness: 95%, calcium content: 98.5%) improves whiteness, brightness, and fireproof performance.

Artificial Marble Industry

Calcium powder for artificial marble (325 mesh, whiteness: 95%, calcium content: 98.5%) is widely used in artificial marble production for its purity and lack of impurities.

Floor Tile Industry

Calcium powder for floor tiles (400 mesh, whiteness: 95%, calcium content: 98.5%) is used to enhance the whiteness, strength, and toughness of floor tiles while reducing production costs.

Heavy Calcium Powder Production Process

The production of heavy calcium powder can be carried out via dry and wet processes.

Dry Process

The dry process is typically used when raw materials are simple, limestone is abundant, and the equipment investment is relatively high.

Raw Material Treatment:

- Crushing: Calcium ores (such as limestone and calcite) are crushed to suitable particle sizes.

- Calcination: The limestone is calcined at high temperatures (usually 900°C to 1000°C), converting it into quicklime (calcium oxide).

Reaction Process:

- Hydration: Quicklime is reacted with water to produce calcium hydroxide. This is an exothermic reaction, and the resulting calcium hydroxide is further processed and finely ground.

Fine Grinding and Packaging:

- Fine Grinding: The hydrated product is finely ground and classified to achieve the desired particle size and product quality.

- Packaging: The processed heavy calcium powder is packaged in compliance with hygiene standards and safety requirements before storage and sale.

Wet Process:

The wet process is suitable for raw materials with high silicate content or other difficult-to-process elements and when a finer, higher-purity product is required.

Packaging: The final product is packaged, adhering to hygiene and safety standards, before storage and sale.

Raw Material Treatment:

Leaching: Calcium ores are leached to obtain a solution, typically using acids or other solvents.

Precipitation: By adding suitable reagents (such as sodium hydroxide), the calcium components in the solution precipitate as solid matter.

Reaction Process:

Precipitated Calcium: The precipitated calcium compounds (e.g., calcium carbonate) are filtered, washed, and dried to yield heavy calcium powder.

Fine Grinding and Packaging:

Fine Grinding: The wet-precipitated heavy calcium powder is finely ground to achieve the required particle size and quality.

Classification of Calcium Carbonate Powders

The screening of calcium powder refers to grading it based on particle size to obtain products within the desired size range. Screening is a crucial step in calcium powder production, as the particle size directly affects its performance in different applications. Below are the basic steps and common methods for screening calcium powder:

Pre-treatment:

Before screening, raw calcium powder typically undergoes pre-treatment to remove impurities and address dust or agglomerates. This can be done using physical methods (e.g., air separation, magnetic separation) or chemical methods (e.g., acid washing, alkaline washing).

Screening Operation:

The pre-treated calcium powder is fed into screening equipment (such as vibrating screens or air classifiers). The powder is classified by mechanical vibration or air flow.

- Vibrating Screens: A common method where the powder is sorted by layers on a screen.

- Air Classifiers: Particularly useful for fine powders or applications requiring high-precision separation.

Collection and Processing:

After screening, calcium powder is collected in different particle sizes (coarse, medium, fine) to meet specific application needs. Fine or high-precision products may require further fine grinding or screening to achieve higher quality standards.

Importance of Calcium arbonate powders Classification

Product Quality Control: Screening helps control the particle size distribution, ensuring the product meets required technical specifications.

Application Performance: Different applications require specific particle sizes. Correct classification enhances the performance of calcium powder in various fields.

Production Efficiency: Proper screening equipment and methods improve production efficiency, reduce costs, and minimize waste.

Epic Powder

The production and classification of calcium carbonate powders involve precise processes to meet industry-specific needs. With the advanced grinding and air classification equipment of Epic Powder, high-quality, finely ground calcium carbonate powders can be produced, ensuring optimal performance in a variety of applications. Whether it’s for rubber, plastic, paint, or construction, the solutions of Epic Powder offer reliable, cost-effective methods to enhance the functionality and efficiency of calcium carbonate in various industries.