Calcium carbonate is an important chemical material, with abundant raw materials and simple production processes. It has excellent performance and is widely used in rubber, inks, pharmaceuticals, and food industries. In the pharmaceutical field, spheroidized calcium carbonate is an excellent calcium source dietary supplement. Calcium carbonate-based calcium supplements have high calcium content, good absorption, and high bioavailability. Pharmaceutical-grade calcium carbonate can be used as a base and filler for some pharmaceuticals. It can also be used to prepare fermentation media, providing calcium and maintaining pH stability. Spheroidized calcium carbonate is indispensable as a buffer in biological fermentation processes. Notably, calcium carbonate is used as a typical biomaterial to construct smart carriers for gene, enzyme, and drug delivery.

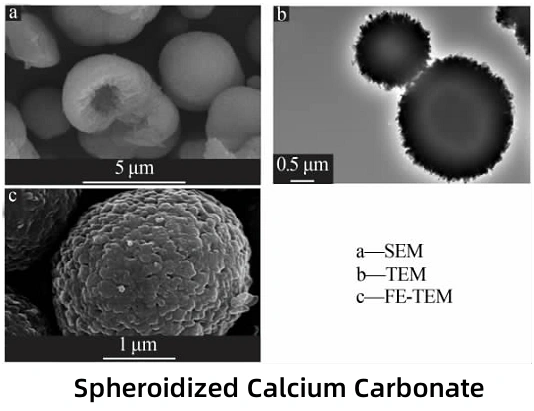

Spheroidized Calcium Carbonate

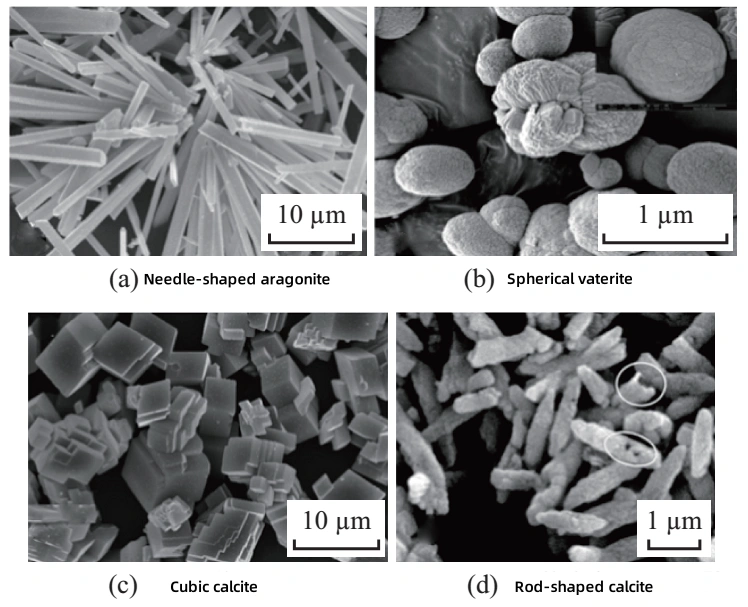

Calcium carbonate mainly has three crystal forms: calcite, aragonite, and spheroidized. Spheroidized calcium carbonate is an orthorhombic crystal, with slight differences from calcite in its unit cell structure. Its unit cell contains carbonate ions and calcium ions, arranged symmetrically and orderly, giving it a spherical shape. Spheroidized calcium carbonate is rarely found in nature and is usually composed of nanometer-sized polycrystalline spherical particles. Unlike calcite and aragonite, spheroidized calcium carbonate is not a single crystal. In addition, spheroidized calcium carbonates can also have disk, flake, hexagonal, and lens-like morphologies. Spherical spheroidized calcium carbonate is considered the most promising type of calcium carbonate for applications.

Among the three common crystalline forms of calcium carbonate, calcite is the most thermodynamically stable. Aragonite is next, while spheroidized calcium carbonate is the least stable form. In aqueous solutions, it easily transforms into the more thermodynamically stable calcite or aragonite. Adding certain substances in different environments can stabilize spheroidized calcium carbonates and slow its conversion to calcite.

Studies show that different synthesis conditions, additives, and post-treatment methods can make the crystal form of calcium carbonate microspheres controllable. Based on this, adjusting temperature, pH, and time can control and selectively synthesize calcium carbonate microspheres. By analyzing the formation pathways and unit cell structure of spheroidized calcium carbonate, its morphology, size, and properties can be effectively regulated.

Compared to the other two crystal forms, spheroidized calcium carbonates not only has conventional properties, such as low density, white color, tastelessness, acid decomposition, and chemical stability, but also features a hollow or porous structure, uniform particle size distribution, micro-nano size, high hydrophilicity, large specific surface area, good solubility and dispersibility, better biocompatibility and safety, good degradability, strong phase transition ability, and spherical distribution. Therefore, spheroidized calcium carbonate has broad application prospects as an inorganic drug carrier material.

Synthesis Methods of Porous Spheroidized Calcium Carbonates Microspheres

Coprecipitation

The co-precipitation method is a common and cost-effective way to synthesize calcium carbonate. By adding a carbonate source, such as sodium bicarbonate, to a calcium chloride or calcium hydroxide solution, calcium carbonate precipitation can be achieved. This method is simple to operate, low-cost, and suitable for large-scale calcium carbonate synthesis.

Hydrothermal Synthesis

The hydrothermal synthesis method is based on a high-temperature, high-pressure solution environment. Under these conditions, the solution exhibits special properties, such as high solubility, high diffusivity, and ion activity. This method is also very convenient for synthesizing calcium carbonate, allowing the control of crystal form, size, and morphology by adjusting reaction conditions and time. It offers good crystal control, enabling the production of calcium carbonate microparticles with good crystallinity and specific morphology.

Microemulsion Method

Microemulsion, also known as nanoemulsion, is primarily used for synthesizing nanoparticles. The solution co-precipitation method involves mixing two or more oil-phase precursor solutions while simultaneously carrying out a precipitation reaction to synthesize calcium carbonate.

Biomineralization

Biomineralization refers to the process of forming inorganic minerals through biological processes in living organisms.

Calcium Carbonate Microspheres as Pharmaceuticals Carriers

The porous morphology and well-developed internal structure of spheroidized calcium carbonate allow it to accommodate molecules with various properties. These particles can effectively capture a wide range of bioactive substances, including low molecular weight compounds and macromolecules, by physically adsorbing (diffusing) into the pores or co-precipitating (co-synthesizing) during particle formation. Spheroidized calcium carbonates microspheres, with adjustable particle size and pH sensitivity, are more suitable for pharmaceutical and gene delivery.

Conclusion

Currently, calcium carbonate is mainly used as a pharmaceutical carrier for oral pharmaceutical, cancer treatment, topical pharmaceuticals, bone repair materials, and gene delivery. Although spheroidized calcium carbonate is a metastable crystal form that does not exist in nature, its unique porous morphology, high specific surface area, good permeability, and biodegradability, as well as its lack of toxic side effects on normal cells, make it highly promising. It shows great potential in biomedical fields such as pharmaceutical-controlled release carriers and gene therapy carriers, attracting increasing attention and research.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !