Currently, the amount of fillers and pigments used in papermaking ranks second only to fiber as one of the most important raw materials. Common papermaking fillers include calcium carbonate, talc, kaolin, wollastonite, bentonite, and others. As the acidic papermaking process gradually shifts towards neutral and alkaline processes, calcium carbonate, as an important raw material in papermaking, is being used more and more in the paper industry.

The Role of Calcium Carbonate in the Paper Industry

Calcium carbonate is primarily used in papermaking in two main ways: as a papermaking filler and as a coating pigment.

Filler

Papermaking fillers are fine, white mineral powders that are generally insoluble or slightly soluble in water. The main purposes of adding fillers to paper are as follows:

- Fillers disperse between fibers in the pulp, filling the voids, improving the paper’s optical properties such as opacity and brightness.

- Improve the paper’s ink absorption, making it more suitable for printing.

- Meet certain specific requirements for paper properties, such as improving conductivity or heat resistance.

- Reduce the use of fiber raw materials, thereby lowering production costs.

- Fillers have a large specific surface area, helping to overcome resin issues.

The advantages of using calcium carbonate as a papermaking filler include:

- Abundant source and low cost.

- Fine particles, high whiteness, and significantly improved paper opacity.

- Fast ink absorption, improving the ink receptivity of the paper.

- Makes the paper softer, denser, and gives it a high gloss.

- Has little effect on the paper’s physical strength.

The amount of filler added is mainly determined by factors such as the type of paper, the type of pulp, the properties of the filler itself, and the papermaking conditions. To save on fiber consumption and reduce production costs, the filler amount should be appropriately increased while ensuring that the paper meets the production and usage requirements.

Coating

The purpose of coating is to improve the quality and uniformity of the final printed paper or paperboard. The main goal of coating pigments is to achieve better optical properties, smoothness, and gloss. The most important factor is achieving a better printing visual effect. Paper coatings typically consist of pigments, binders, additives, and water, with pigments being the most critical. The characteristics of coated paper depend largely on the choice of pigment.

Due to its high whiteness and good flowability, calcium carbonate is suitable for preparing high-solids-content coatings. It requires less binder, improving the ink absorption of the coating. It also provides good whiteness and tone, enhancing permeability. Calcium carbonate is one of the most commonly used coating pigments.

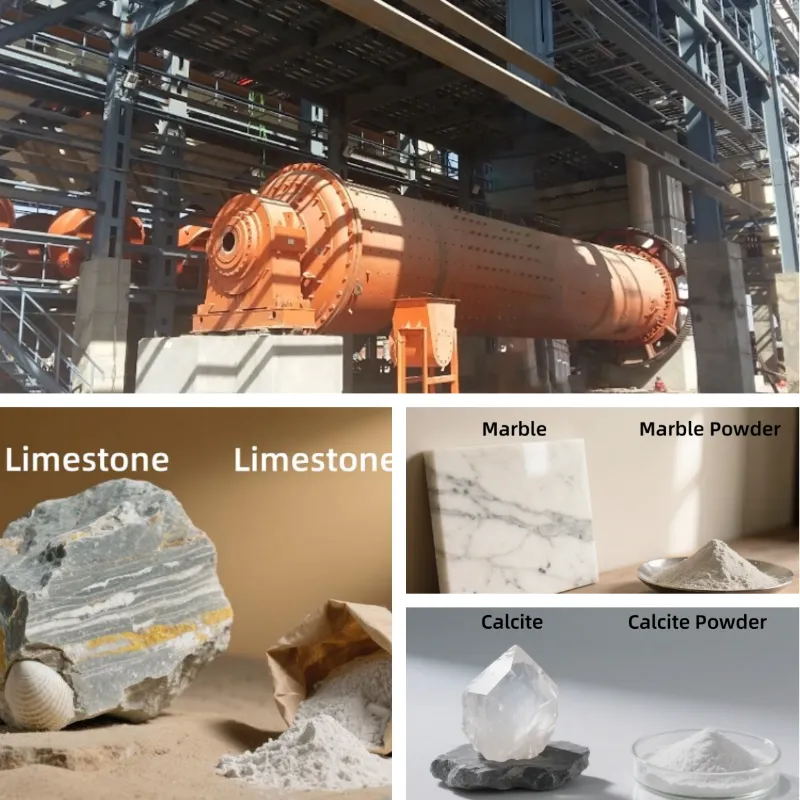

Differences in the Application of Ground Calcium Carbonate (GCC) and Precipitated Calcium Carbonate (PCC) in the Paper Industry

Ground calcium carbonate (GCC) is mainly used as a filler in printing paper, writing paper, office paper, and advertising paper, excluding cigarette paper, filter paper, and special low grammage paper. Precipitated calcium carbonate (PCC) can be applied to all types of paper, but is currently mainly used as a filler in high-grade papers, such as cigarette paper, office information papers (e.g., fax paper, instrument record paper, inkjet paper), low grammage newsprint, and low grammage coated paper. Both GCC and PCC have their advantages as papermaking fillers, and the choice of which type to use depends on the specific requirements of the paper production process.

- GCC has better flowability than PCC and saves binder usage in coatings, making it suitable for high-solid-content coatings and increasingly high-ratio formulations.

- Due to the higher manufacturing cost of PCC and its relatively poor rheological properties, it cannot yet compete with GCC in coating applications.

However, modified PCC or finer nanoparticles of calcium carbonate have been widely recognized for their functional applications in the paper industry. They help to give paper specific properties while reducing costs. Their impact on paper quality includes the following aspects:

Stiffness

The stiffness of paper is a function of its thickness and elastic modulus. The effect of fillers on stiffness should consider both the influence on bulk density and tensile strength.

- When the filler content is low, the addition of fillers has little effect on the paper’s stiffness.

- When the filler content increases, the stiffness significantly decreases with the increasing amount of filler.

Density (Bulk Density)

The density of paper fibers is 1 gram per cubic centimeter, while the density of most fillers is between 2.5 to 3.0 grams per cubic centimeter. Therefore, the addition of fillers changes the paper’s bulk density.

Paper Strength

The strength of paper is based on the bonding between fibers, and the addition of fillers reduces fiber bonding. Therefore, adding too many fillers can significantly reduce the strength of the paper. This is most noticeable in terms of tensile strength, fold endurance, and burst strength, while tear strength is less affected. The use of certain papermaking additives can help reduce the strength loss.

Improvement of Opacity

Paper without fillers consists of fibers and air. Air occupies the voids between fibers, and since the refractive index of air differs from that of the fiber, part of the light is scattered at the fiber-air interface, giving the paper a certain (relatively low) opacity. This results in poor opacity in printing.

By adding calcium carbonate, which has a higher refractive index than cellulose, the number of scattering interfaces within the paper increases. Specifically, there are three types of interfaces: fiber-air, filler-fiber, and filler-air. The largest scattering occurs at the filler-air interface, thus increasing the opacity of the paper.

Impact on Printing Paper Performance

Adding calcium carbonate to printing paper improves the paper’s printability, such as increasing brightness, smoothness, opacity, and stiffness. It also improves ink affinity, softness, and stability, which helps enhance the quality of printed products.

Of course, adding too much filler can lead to some negative effects, primarily the reduction in paper strength and sizing performance. This may result in issues like paper dusting, fuzzing, or ink smearing during printing. Fillers can also wear out the printing plates due to friction, but using PCC can minimize this effect.

Impact on Special Paper Properties

Research on nanocalcium carbonate shows that adding nanocalcium carbonate fillers in papermaking can give paper the following characteristics:

- It slows down the aging process of paper, allowing it to be preserved for a longer time.

- It can absorb certain amounts of UV light.

- It prevents paper from yellowing and becoming brittle, and it provides good isolation properties.

When used as a coating pigment, nanocalcium carbonate helps improve the gloss, whiteness, and hue of the coating layer. It ensures the purity of white pigments and enhances opacity, gloss, and printing gloss. It can also change the rheological properties of coating preparation liquids and enable functional coatings such as insulation, conductivity, and antibacterial properties. Nanocalcium carbonate as a papermaking filler is mainly used in the production of specialty paper products, such as diapers, sanitary napkins, photo inkjet paper, tissues, and breathable membranes.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !