Calcium powder (CaCO3) (mainly calcium carbonate powder) is an important industrial filler widely used in multiple industries. Due to its stable chemical properties, non-toxicity, and abundant availability, calcium powder not only enhances product quality but also effectively reduces production costs. With varying particle sizes and purity, calcium powder plays a crucial role in industries such as rubber, plastics, paints, water-based coatings, paper, construction, and floor tiles. Below are the primary uses and functions of calcium powder in these industries:

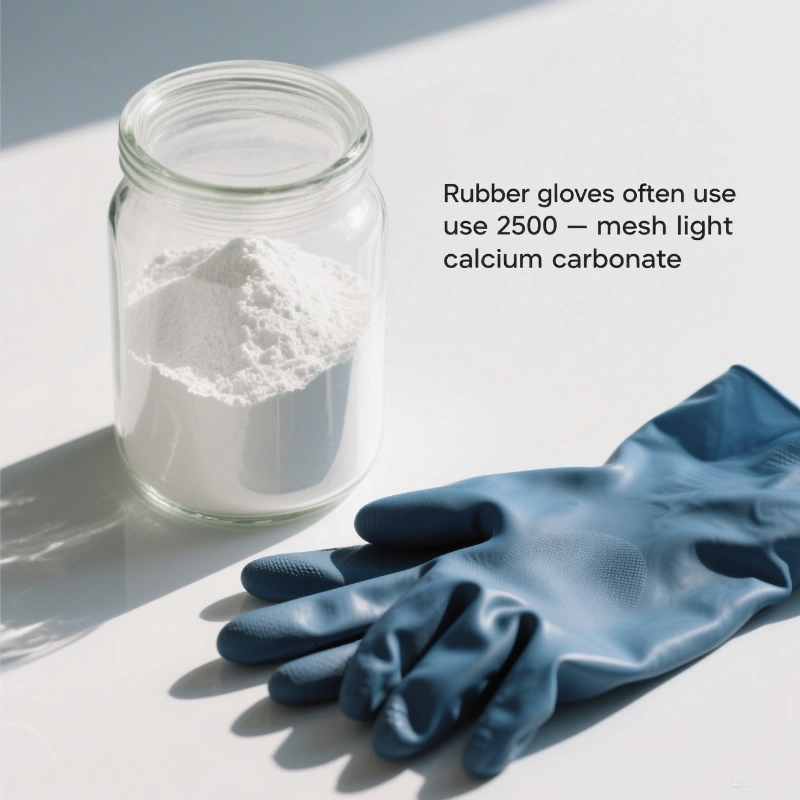

Rubber Industry Calcium Powder (CaCO3)

Calcium powder (400 mesh, whiteness: 93%, calcium content: 96%) is one of the most commonly used fillers in the rubber industry. By filling a large amount of calcium powder into rubber, it increases the volume of the products and saves on expensive natural rubber, significantly lowering costs. The addition of calcium powder improves tensile strength, tear strength, and wear resistance compared to pure rubber vulcanizates.

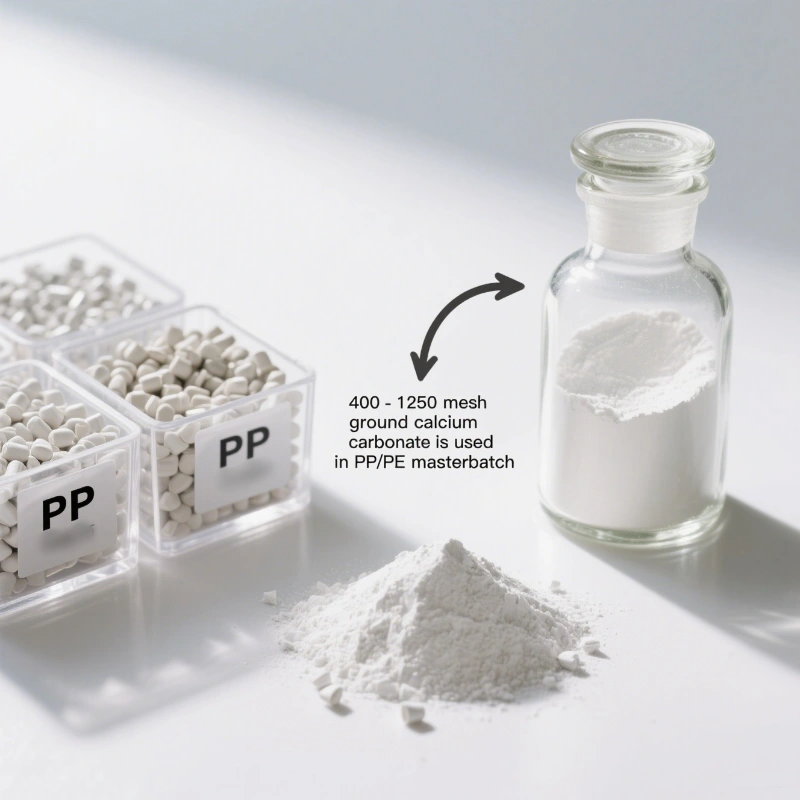

Plastic Industry Calcium Powder (CaCO3)

Calcium powder (400 mesh, calcium content: 99%, whiteness: 95%) is used in plastic masterbatches and color masterbatches. After high-temperature heating, the whiteness remains unchanged. Calcium powder acts as a structural filler, improving the dimensional stability of plastic products. It also enhances the hardness, surface gloss, and smoothness of the products. Due to its whiteness of over 90%, it can replace expensive white pigments.

Paint Industry Calcium Powder

Calcium powder (800 mesh or 1000 mesh, whiteness: 95%, calcium content: 96%) is widely used in paints and latex paints. In thick paints, calcium powder usage can exceed 30%. It helps increase the viscosity, covering power, and enhances the texture of the paint.

Water-Based Coatings Industry Calcium Powder

Calcium powder (800 mesh or 1000 mesh, whiteness: 95%, calcium content: 96%) is more widely used in water-based coatings. It helps prevent sedimentation, promotes easy dispersion, and improves gloss. The usage of calcium powder in water-based coatings can range from 20% to 60%.

Paper Industry Calcium Powder

For paper production, heavy calcium powder (325 mesh, whiteness: 95%, calcium content: 98%) is used. It ensures the strength and whiteness of the paper and reduces the cost of production.

Construction Industry (Dry Mortar, Concrete) Calcium Powder

Calcium powder (325 mesh, whiteness: 95%, calcium content: 98%) is important in the construction industry. It lowers the production cost of concrete and dry mortar while enhancing the flexibility, strength, and durability of the products.

Fireproof Ceiling Industry Calcium Powder

Fireproof ceilings use calcium powder (600 mesh, whiteness: 95%) to improve the product’s whiteness, brightness, and fire resistance.

Artificial Marble Industry Calcium Powder

Calcium powder (325 mesh, whiteness: 95%, calcium content: 98%) is used in the production of artificial marble. It helps increase the product’s whiteness and hardness, and it ensures that the final product is pure and free of impurities.

Floor Tile Industry Calcium Powder

Calcium powder (400 mesh, whiteness: 95%) is used in the production of floor tiles. It increases the whiteness, tensile strength, and flexibility of the tiles, while lowering production costs.

Epic Powder

Calcium powder’s role in various industries is becoming increasingly prominent, making it an indispensable material in many industrial products. To ensure the high quality and stability of calcium powder, precise grinding equipment and technology are required during production. Epic Powder, a professional provider of ultrafine grinding equipment, offers efficient solutions for calcium powder processing. Whether it’s improving particle size distribution or conducting surface modifications, Epic Powder’s advanced equipment, including ball mills and air classifiers, can meet the high standards required for calcium powder in different applications. Through precise grinding technology, Epic Powder ensures that calcium powder performs effectively across industries, driving more efficient and environmentally friendly industrial production.