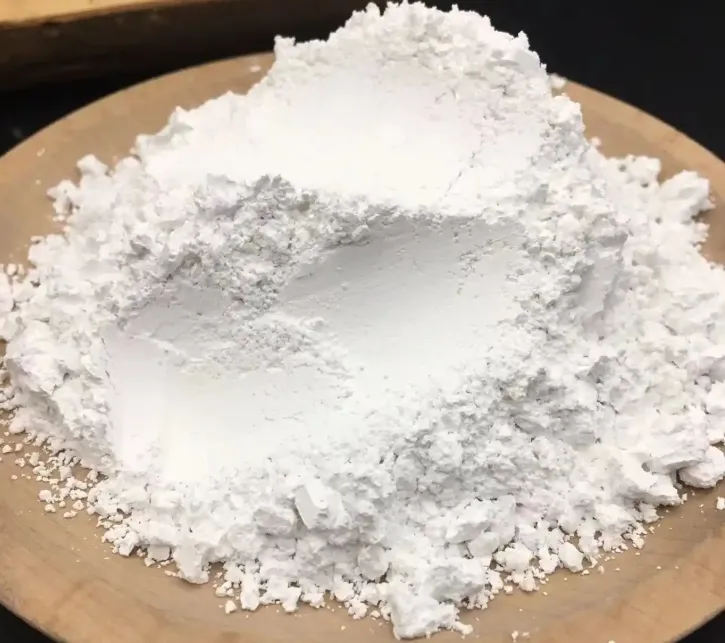

Heavy calcium carbonate is a powder material made from limestone, chalk, marble, and other ores. It is produced by mechanical grinding methods. It has wide raw material sources, high whiteness, low oil absorption, and good applicability. It is low-cost and the most widely used inorganic non-metallic mineral powder product.

Currently, the fine processing technology of heavy calcium carbonate mainly focuses on grinding and surface modification. This produces products that meet the fineness requirements of different application fields. These include fine powder, ultra-fine powder, surface-modified (activated) powder, and ultra-fine slurry for papermaking. There are more than ten types of specialized heavy calcium carbonate products with different fineness and surface modifications.

Heavy calcium carbonate grinding technology and equipment

Currently, ordinary heavy calcium carbonate with a D97 ≥ 5 μm is mainly produced by dry methods. The equipment used includes improved Raymond mills (suspension roller mills or swing mills), roller mills (such as press roller mills, vertical mills, and ring roller mills), and ball mills.

Ultra-fine heavy calcium carbonate with D97 ≥ 5 μm is generally produced using dry processing methods. Some production processes use wet grinding + drying. Dry processing mainly involves ball mills with classifiers. It also includes roller mills, such as ring roller mills with internal classification. Other methods use vertical mills or press roller mills. Dry stirred mills with classifiers are also used in the production process.

For papermaking coating-grade ultra-fine heavy CaCO₃ slurries with D97 ≤ 5 μm, especially D90 ≤ 2 μm, wet processing is generally used. The main equipment for this process includes stirred mills and sand mills.

The ball mill + classifier production line is mainly used to produce heavy calcium carbonate fine powders and ultra-fine powders with D97 = 5–43 μm. Its features include continuous closed-loop production, multi-stage classification, large circulation load (300%–500%), and high single-machine production capacity. This production line has been in use since the late 1990s and is one of the main technologies for large-scale ultra-fine CaCO₃ production lines worldwide.

The roller mill has been the most widely used fine and ultra-fine grinding equipment in China’s heavy CaCO₃ industry over the past decade. It features a large crushing ratio and relatively low energy consumption per unit of product. With internal or external fine classifiers, it can produce ultra-fine products with D97 ≤ 10 μm. The product fineness can be adjusted between D97 = 5–40 μm. The most suitable product particle size range is D97 = 10–30 μm.

Heavy calcium carbonate surface modification technology and equipment

Surface modification of heavy calcium carbonate mainly uses organic coating and composite modification methods. Organic coating modification uses organic substances, such as stearic acid, aluminum or titanium coupling agents, and water-soluble polymers. These are used as surface coating/modifying agents to modify the heavy calcium carbonate powder. Composite modification uses physical or chemical methods to evenly mix or coat another inorganic powder on the surface of heavy or ultra-fine heavy CaCO₃.

Currently, dry modification is the mainstream process for heavy CaCO₃.

Wet modification is rarely used, except when employing wet ultra-fine grinding processes.

Currently, dry modification is the mainstream process for Ground calcium carbonate.

Wet modification is rarely used, except when employing wet ultra-fine grinding processes.

Common surface modification equipment for heavy calcium carbonate includes pin mill coating machine, three-roller coating machine, turbo mill coating machine, and cell mill coating machine.

Development trend of fine processing technology of heavy calcium carbonate

Currently, the production capacity of ordinary heavy CaCO₃ has reached saturation, and the product price is low, with limited technological content and added value. However, for ultra-fine and activated Ground calcium carbonate, the production capacity still cannot meet demand and has significant market potential. Overall, the main development trends in the heavy calcium carbonate industry are large-scale production, functionality, and automation.

These trends are essential for intensive, stable, and optimized production. They aim to improve production efficiency, reduce energy consumption, wear, and costs. These trends are also driven by the significant increase in market demand. They are further influenced by the need to reduce resin usage in high polymer-based composite materials.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !