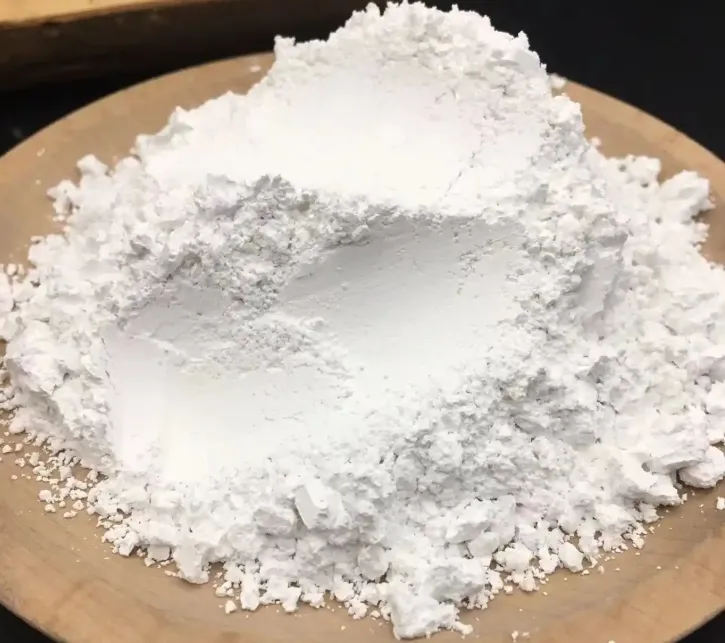

Heavy calcium carbonate, also known as heavy calcium, is a colorless, tasteless white powder. It is almost insoluble in water and alcohol, but reacts with dilute acetic acid, hydrochloric acid, and nitric acid. It fizzes and dissolves when exposed to these acids. When heated to 898°C, it decomposes into calcium oxide and carbon dioxide. The uses of heavy calcium carbonate is inorganic filler, which is ground from natural carbonate minerals such as calcite, marble, and limestone. It is chemically stable, does not easily react, and has good thermal stability. It does not decompose below 400°C, has high whiteness, low oil absorption, and low refractive index. It is soft, dry, free of crystallized water, has low hardness and abrasion, and is non-toxic, odorless, and tasteless. It also has good dispersibility.

Heavy calcium carbonate is widely used as a filler in industries such as artificial tiles, rubber, plastics, paper, coatings, paints, inks, cables, building materials, food, pharmaceuticals, textiles, feed, and toothpaste. As a filler, it helps increase product volume and reduce production costs. In rubber, it can increase the volume, improve processability, provide semi-reinforcement or reinforcement, and adjust rubber hardness.

The uses of heavy calcium carbonate

Coal-fired power generation industry

In coal-fired power plants, heavy calcium carbonate powder is used for flue gas desulfurization. Flue gas desulfurization involves reacting heavy calcium carbonate with sulfur dioxide produced during coal combustion to form calcium sulfite. This then oxidizes to gypsum (calcium sulfate) when exposed to air, effectively reducing sulfur dioxide emissions by up to 90%. The produced desulfurization gypsum can be sold directly to cement plants or gypsum board manufacturers. The amount of desulfurization calcium carbonate powder used is related to the sulfur content in the coal. Typically, a 300,000 kW coal-fired power plant requires 40,000 tons of desulfurization powder annually.

Rubber Industry

Heavy calcium carbonate is one of the most widely used fillers in the rubber industry. By filling rubber with a large amount of heavy calcium carbonate, the volume of the products is increased, and expensive natural rubber is saved, significantly reducing costs. Adding heavy calcium carbonate to rubber results in higher tear strength and wear resistance compared to pure rubber vulcanizates.

Plastics Industry

Heavy calcium carbonate powder with a 400 mesh size is used in plastic masterbatches and color masterbatches. It is required to maintain whiteness after high-temperature heating, with the mineral structure being large crystal calcite. The calcium carbonate content is 99%, and the whiteness is 95%. In plastic products, heavy calcium carbonate serves as a structural framework, greatly enhancing the dimensional stability of the products. It also improves the hardness, surface gloss, and surface flatness of the products.

Paint Industry

The heavy calcium carbonate powder used in latex paint is 800 mesh or 1000 mesh, with a whiteness of 95% and calcium carbonate content of 96%.

Heavy calcium carbonate is widely used in the paint industry, with its usage in thick paints exceeding 30%.

Water-based coatings industry

The heavy calcium carbonate powder used in water-based coatings is 800 mesh or 1000 mesh, with a whiteness of 95% and calcium carbonate content of 96%. Heavy calcium carbonate plays a significant role in the water-based coating industry, providing properties such as non-settlement, easy dispersion, and good gloss. Its usage in water-based coatings ranges from 20% to 60%.

Paper Industry

The heavy calcium carbonate powder used in papermaking is 325 mesh, with a whiteness requirement of 95% and calcium carbonate content of 98%. Heavy calcium carbonate plays a crucial role in the paper industry, ensuring the strength and whiteness of the paper, while keeping costs low.

Feed and fertilizer industry

In the feed industry, heavy calcium carbonate powder is used as a calcium supplement, replacing the traditional shell powder to reduce costs. In the fertilizer industry, heavy calcium carbonate with varying whiteness is used to aid in fertilizer granulation and color adjustment.

Construction industry (dry mortar, concrete)

The heavy calcium carbonate powder used in dry mortar is 325 mesh, with a whiteness requirement of 95% and calcium carbonate content of 98%. Heavy calcium carbonate plays an important role in concrete in the construction industry, not only reducing production costs but also increasing the product’s toughness and strength.

Conclusion

In conclusion, heavy calcium carbonate is a versatile and widely used material across various industries. Its applications span from construction and paints to rubber, plastics, and feed, offering benefits such as cost reduction, enhanced product strength, and improved performance. As a highly effective filler, heavy calcium carbonate continues to play a significant role in improving the quality and functionality of numerous products, making it an essential ingredient in modern manufacturing processes.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !