High-gloss calcium carbonate (HGCC) is an advanced form of calcium carbonate. It has gained significant attention due to its unique properties. These include excellent whiteness, fine particle size, and high dispersion. This material is used in many applications, from paints and coatings to plastics and paper manufacturing. It enhances product performance and appearance.

Characteristics of High-gloss Calcium Carbonate

High fineness: fineness reaches more than 2500 mesh, filling material pores and improving surface flatness.

High whiteness: gives the product excellent color, suitable for coatings, paper and other fields with high color requirements.

Good dispersion fluidity: after surface modification, it is evenly distributed in the matrix to avoid agglomeration and ensure product stability.

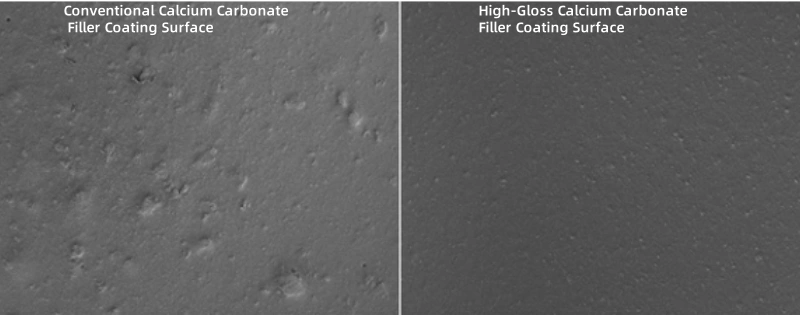

Outstanding gloss: promotes high flatness and high reflection of the paint film, combines with resin to reduce porosity, and does not affect weather resistance.

Strong stability: nano-scale structure prevents sedimentation, UV and heat aging, and extends the service life of the coating.

Enhanced performance: improves the mechanical properties of plastic dimensional stability, strength, etc., and improves the flexibility and water resistance of the coating.

Manufacturing Process

The production of high-gloss calcium carbonate involves several key steps:

a) Crushing and Grinding:

Calcium carbonate is extracted from natural limestone or marble. It is then crushed into smaller particles. The material is ground using advanced grinding technologies, such as ball mills, vibration mills, or jet mills. This achieves the desired fine particle size.

b) Surface Modification:

Surface modification is one of the most important steps in producing HGCC. This process involves coating the calcium carbonate particles with specific agents. These agents improve surface properties, such as dispersion and compatibility with other materials. Coatings also enhance the gloss level, making HGCC ideal for high-shine applications.

c) Classification:

The ground calcium carbonate is subjected to classification. This is done using air classifiers or sieves.

The goal is to separate fine particles from coarser ones. This ensures a narrow particle size distribution.

d) Drying and Final Processing:

After surface modification and classification, the material is dried. Excess moisture is removed before packaging for distribution.

Applications of High-Gloss Calcium Carbonate

a) Paints and Coatings:

HGCC is used in the paints and coatings industry. It provides a glossy finish, high reflectivity, and excellent opacity. It also improves the mechanical properties of coatings, such as scratch resistance and durability.

b) Plastics and Polymers:

In plastics, HGCC acts as a filler to enhance performance. It improves surface gloss, reduces production costs, and increases strength and rigidity. It does not compromise transparency, making it suitable for clear plastics.

c) Paper Industry:

HGCC is used as a filler in paper production. It enhances brightness and opacity, making it ideal for high-quality printing applications. It is commonly used in magazines, brochures, and packaging materials.

d) Pharmaceuticals and Food Products:

HGCC is used as an excipient in tablet formulations. It provides texture, stability, and consistency to tablets and capsules. It is also used as a natural colorant or whitening agent in food products.

Conclusion

The birth of high-gloss calcium can be seen as a new product iteration. It is the result of combining and innovating ultrafine powder processing equipment, such as vertical mills and multiple classification equipment.

Currently, more and more processes are capable of producing high-gloss calcium. This can be achieved through wet ball milling or vertical mills with multiple classification steps. However, foreign companies have already taken the “next step” in high-gloss calcium. They have made breakthroughs in morphology and modification. These advances result in a larger specific surface area and better fluidity and dispersibility. This is a goal that companies must continue to strengthen and catch up with.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !