Surface modification is a crucial method to improve the performance of calcium carbonate. It enhances applicability and expands market usage.

In the future, functionalization and specialization will be the main trends in calcium carbonate development. The demand for various surface-modified specialized calcium carbonate will increase significantly.

Improve the dispersibility of calcium carbonate

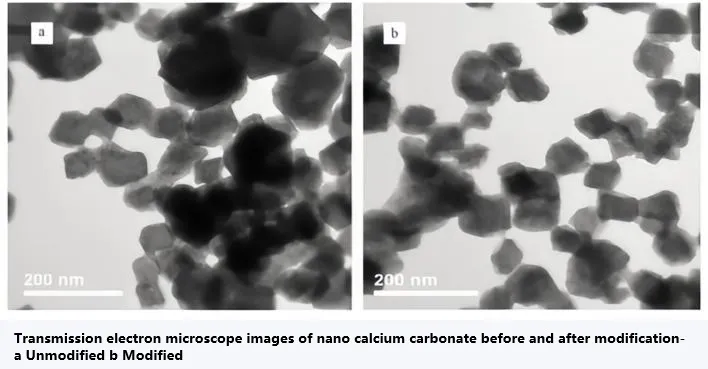

Ultrafine processing is an important way to improve the quality of calcium carbonate. However, as the particle size of calcium carbonate decreases, its surface energy increases. This leads to stronger adsorption and more serious agglomeration.

Surface modification can cause modifiers to adsorb directionally on the calcium carbonate surface. This imparts charge characteristics to the surface.

Due to the repulsion between like charges, calcium carbonate is less likely to agglomerate. As a result, good dispersion is achieved in the matrix.

Improved calcium carbonate compatibility

Surface modification can increase the interfacial compatibility and affinity between calcium carbonate and organic materials, improving its performance in composite products like rubber or plastics.

For example, calcium carbonate treated with titanate coupling agents shows better compatibility with polymer molecules.

Additionally, titanate coupling agents form molecular bridges between calcium carbonate and polymer molecules, enhancing the interaction between the organic polymer or resin and calcium carbonate.

This significantly improves the mechanical properties of thermoplastic composites, such as impact strength, tensile strength, flexural strength, and elongation.

Reduce the oil absorption value of calcium carbonate

Surface modification is an important method to reduce the oil absorption value of powders. After surface modification, calcium carbonate particles form fewer aggregates, improving dispersion. The gaps between particles are reduced, and the modified molecules cover the surface of calcium carbonate.

This coverage reduces the internal gaps of the particles. Additionally, it alters the surface properties of calcium carbonate, weakening its surface polarity.

As a result, the friction between particles decreases, improving lubricity.

This leads to tighter packing, increased bulk density, and reduced oil absorption value.

Expand the high-end application market of calcium carbonate

Unmodified calcium carbonate has poor compatibility, easily agglomerates, and performs poorly. These drawbacks become more obvious as the usage increases.

Through surface modification, calcium carbonate gains good interfacial affinity, and its oil absorption value decreases. It can be better applied in high-end fields such as plastics, coatings, rubber, paper, sealants, and breathable films. This improves product quality and further reduces production costs for application companies.

Giving calcium carbonate more functional properties

Calcium carbonate without surface modification can only be used as a traditional filling material, and its application field and dosage are subject to certain restrictions. Through surface modification, calcium carbonate has been transformed into a multifunctional modifier.

Unmodified calcium carbonate can only be used as a traditional filler, limiting its application areas and usage. Through surface modification, calcium carbonate transforms into a multifunctional modifier. Calcium carbonate coated with silica can partially replace white carbon black and supplement its performance in certain aspects. Lightweight calcium carbonate coated with metals can improve certain special properties of rubber products.

Calcium carbonate composites coated with titanium dioxide can partially replace titanium dioxide. Treating calcium carbonate with phosphates, aluminates, silicates, or barium salts can create acid-resistant calcium carbonate.

Increase the added value of calcium carbonate products

Currently, the calcium carbonate industry faces severe structural contradictions, with significant overcapacity in regular calcium carbonate production. Statistics show that, in recent years, the growth rate of regular calcium carbonate capacity has far exceeded market demand, leading to a backlog of products. In this context, low-price competition between companies has intensified, severely compressing profit margins, and the industry’s development has reached a standstill.

In stark contrast, surface-modified calcium carbonate has opened up new market opportunities due to its significant performance advantages.

For example, in the coatings industry, regular calcium carbonate tends to cause settling and agglomeration, affecting the storage stability and film formation of the coatings.

Surface-modified calcium carbonate greatly improves dispersion, allowing it to evenly distribute within the coating system, effectively enhancing the coverage and gloss of the paint.

Furthermore, modified calcium carbonate has good compatibility with organic resins in coatings, significantly improving adhesion and weather resistance.

This results in a superior user experience, and naturally, the product price increases.

Calcium carbonate surface modification equipment

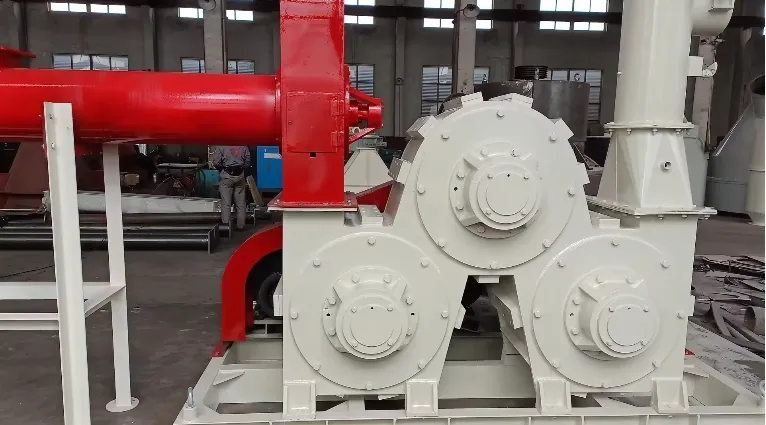

In the field of calcium carbonate modification, pin mill coating machine, three-roller coating machine, turbo mill coating machine, and honeycomb mill coating machine play a crucial role.

With their unique working principles and performance advantages, these machines provide strong support for producing high-quality modified calcium carbonate products.

Pin mill coating machine: This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industry.

Three-roller coating machine: This continuous powder surface coating system is designed on the base of German know how with Chinese equipment, and can be used for coating of various powders like calcium carbonate (GCC, PCC), kaolin, talc, mica, graphite, barium sulfate, white carbon black, magnesium hydrate, zinc oxide, aluminum oxide, and is suitable for a variety of solid/liquid coating agents, like aluminate coupling agent, titanate coupling agent, silane coupling agent and stearic acid.

Turbo mill coating machine: EPIC Powder combines advanced powder modification technology at home and abroad, and independently developed UCOAT series continuous modification equipment. The modification rate of vortex mill coating machine is up to 99%, and the product quality is stable.

Honeycomb mill coating machine: Honeycomb mill is a mechanical grinding machine that advocates the practical process of first depolymerization and then drying, and synchronous surface treatment. It is specifically designed for the production of ultrafine powders with strict requirements for particle size distribution.

EPIC powder contact details

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert!