Welcome to Qingdao To Attend The 22nd AP-RubberPlas

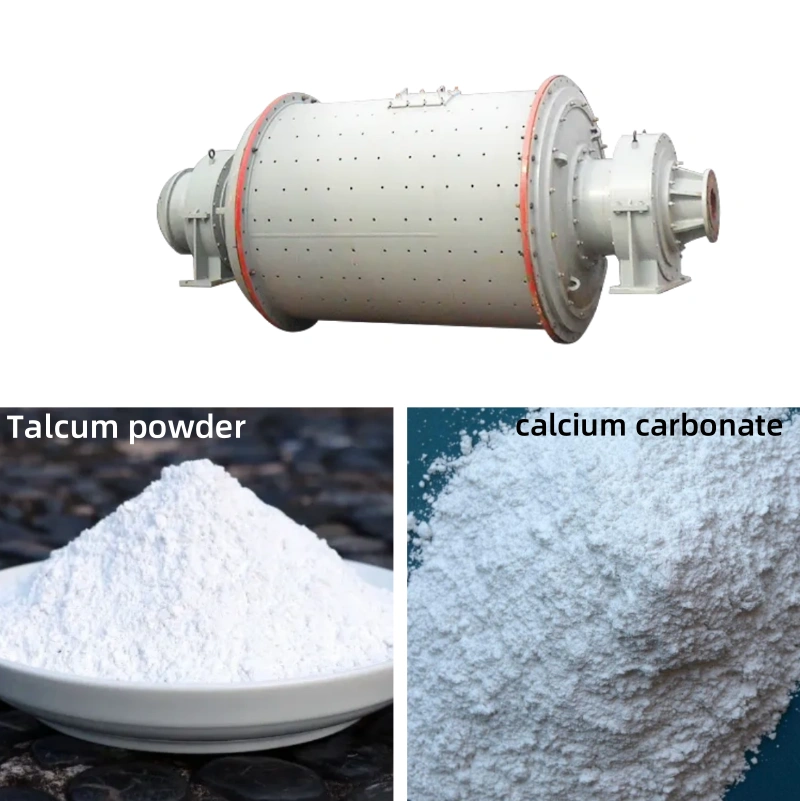

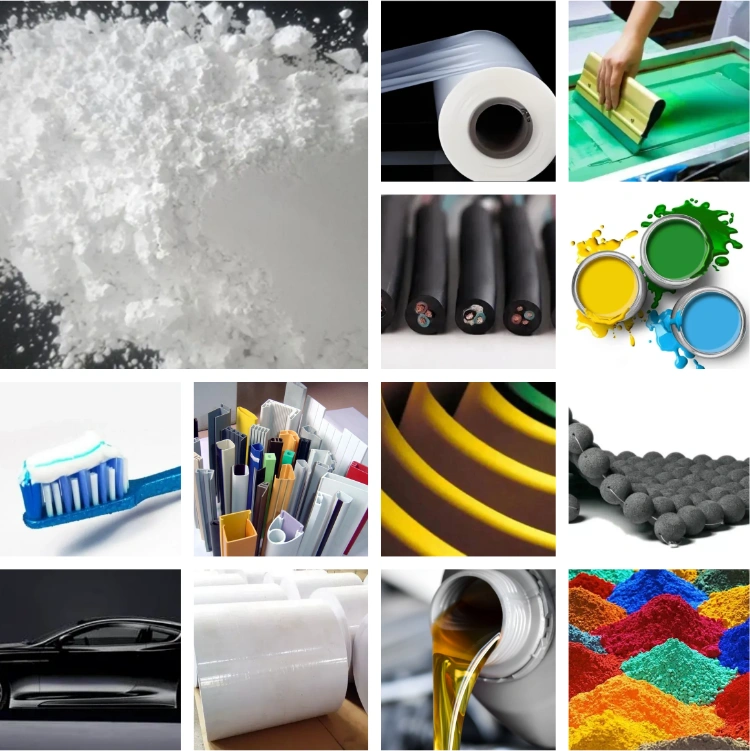

Qingdao EPIC Powder Machinery Co.,ltd. sincerely invites you to participate in the The 22nd Asia Pacific International Plastics and Rubber Industry Exhibition. 10-13 July 2025 , No. 3399, Sansha Road, West Coast New District, Qingdao City, Shandong Province.Booth No. Booth No.Hall S3 C77 Epic Powder Epic Powder, 20+ years of work experience in the ultrafine powder […]

Welcome to Qingdao To Attend The 22nd AP-RubberPlas Read More »