What is a Ball Mill Classifier System for Calcium Carbonate?

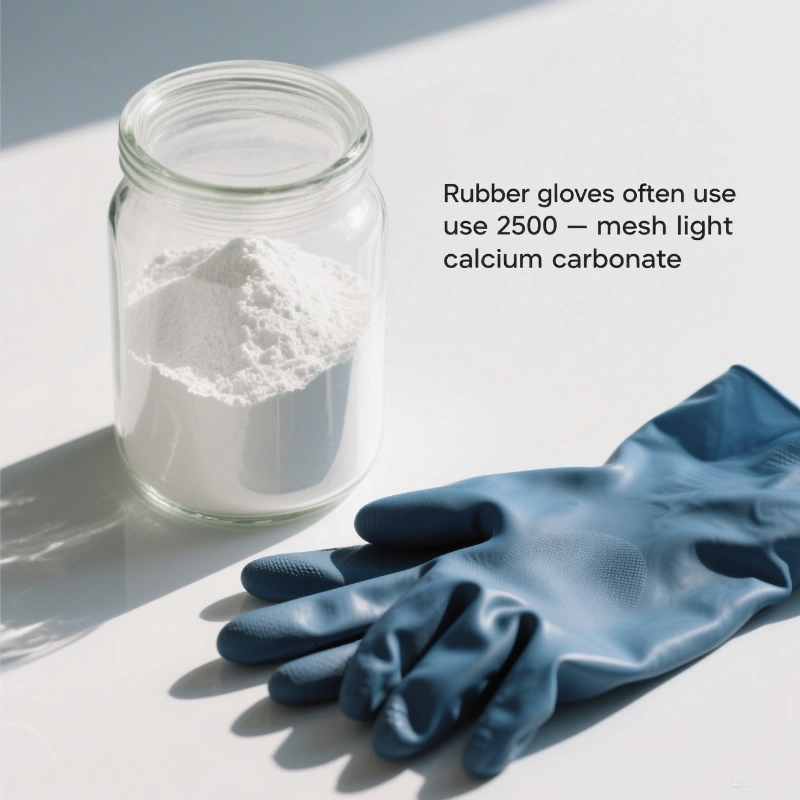

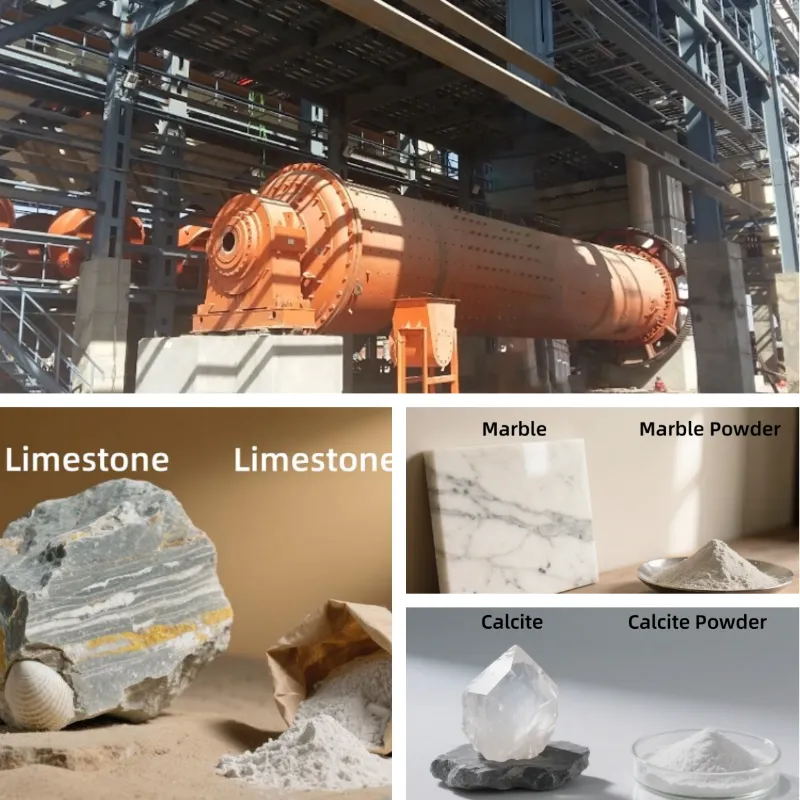

Calcium carbonate (CaCO₃) is one of the most widely used inorganic mineral powders today. With abundant resources, low cost, and excellent performance, it is extensively applied in plastics, rubber, paper, coatings, building materials, and other industries. As downstream industries demand higher product performance, calcium carbonate powders must not only achieve specific particle size ranges but […]

What is a Ball Mill Classifier System for Calcium Carbonate? Read More »